Pre-Eng. Buildings

Cranes Shed

Cranes Shed

Cranes Shed

Heavy-Duty Industrial Shed for 50 MT & 75 MT Crane System

Heavy-Duty Industrial Shed for 50 MT & 75 MT Crane System

Heavy-Duty Industrial Shed for 50 MT & 75 MT Crane System

Year

2025

Year

2025

Year

2025

Industry

Construction / Steel Fabrication

Industry

Construction / Steel Fabrication

Industry

Construction / Steel Fabrication

Project Duration

4 weeks

Project Duration

4 weeks

Project Duration

4 weeks

Intro

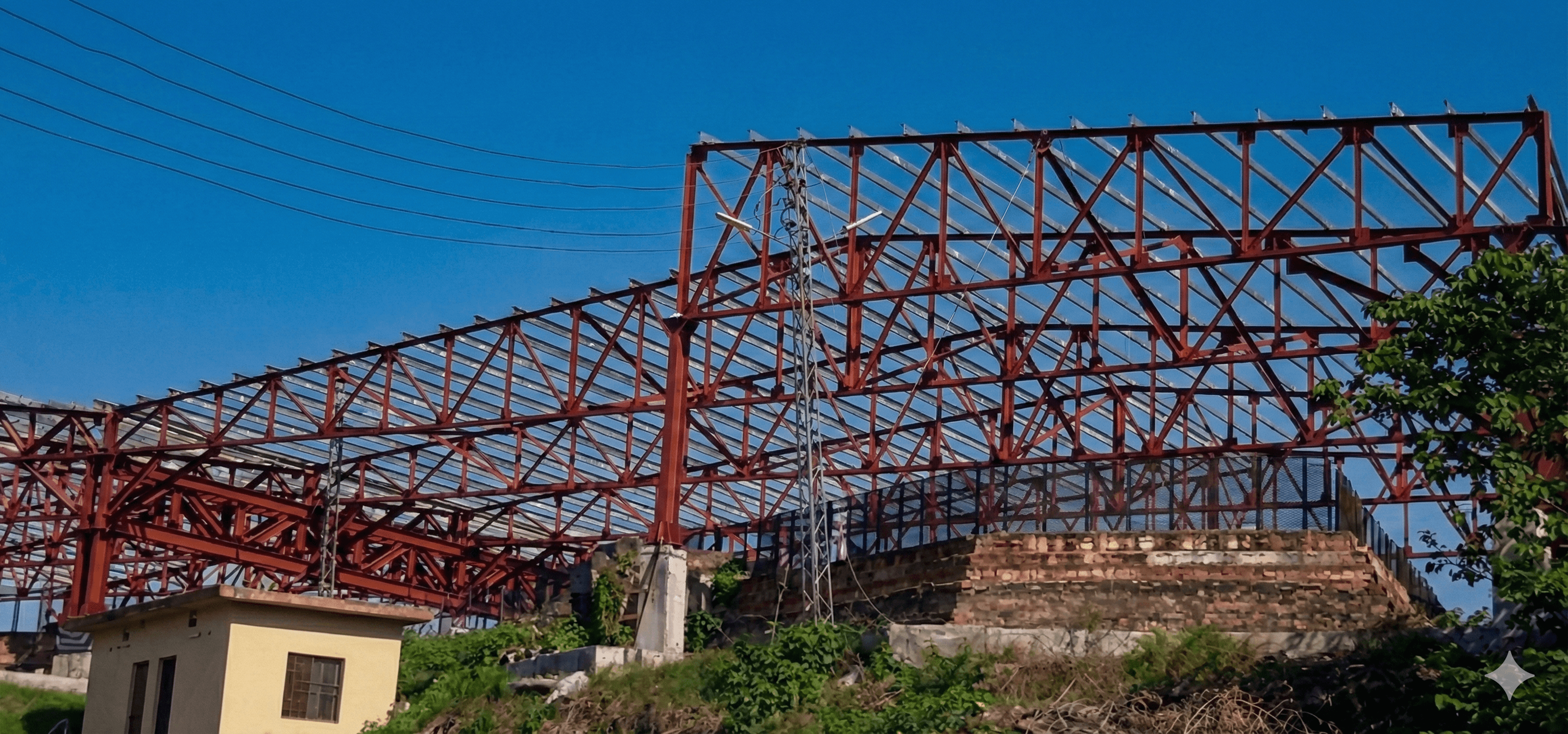

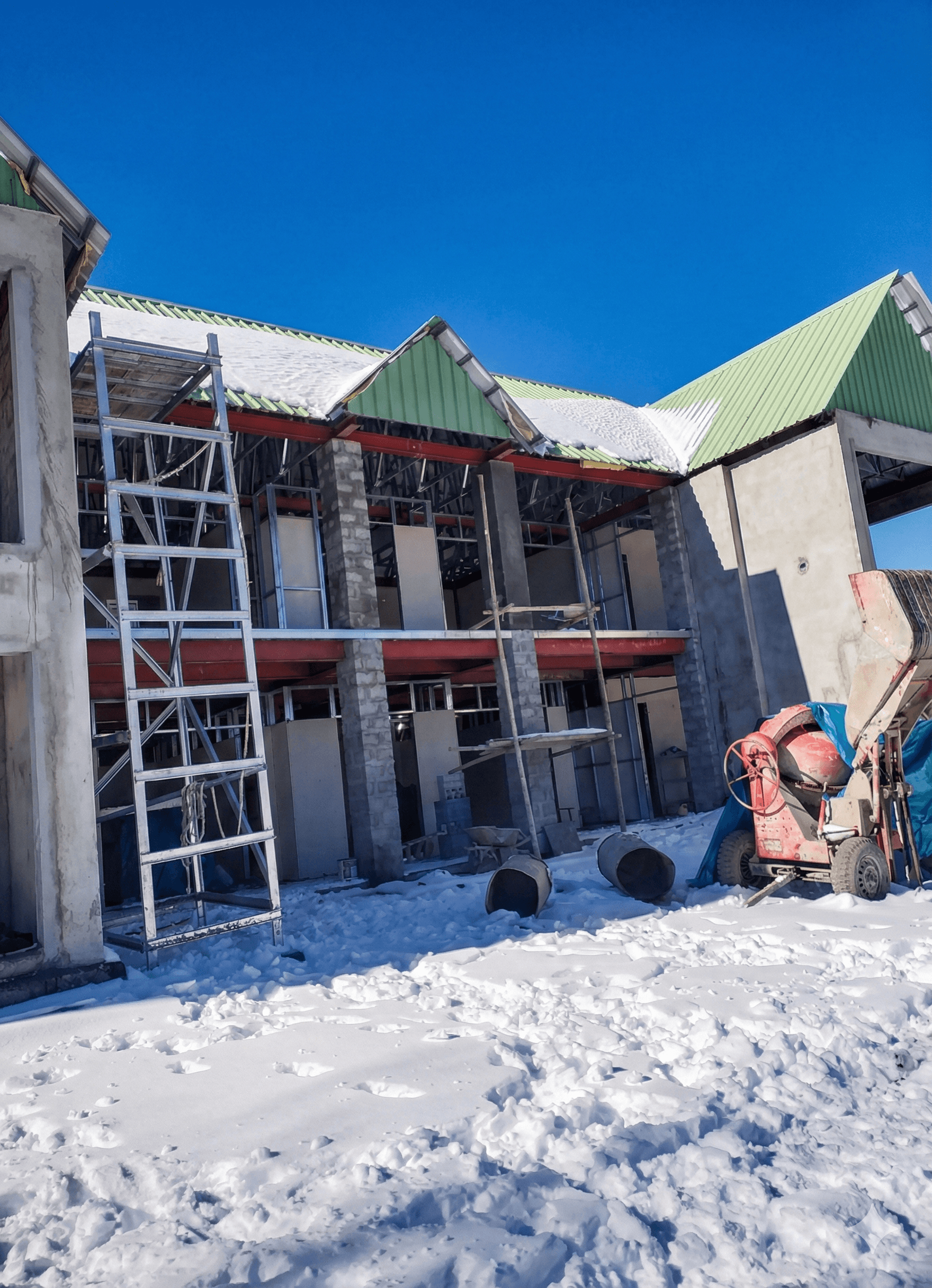

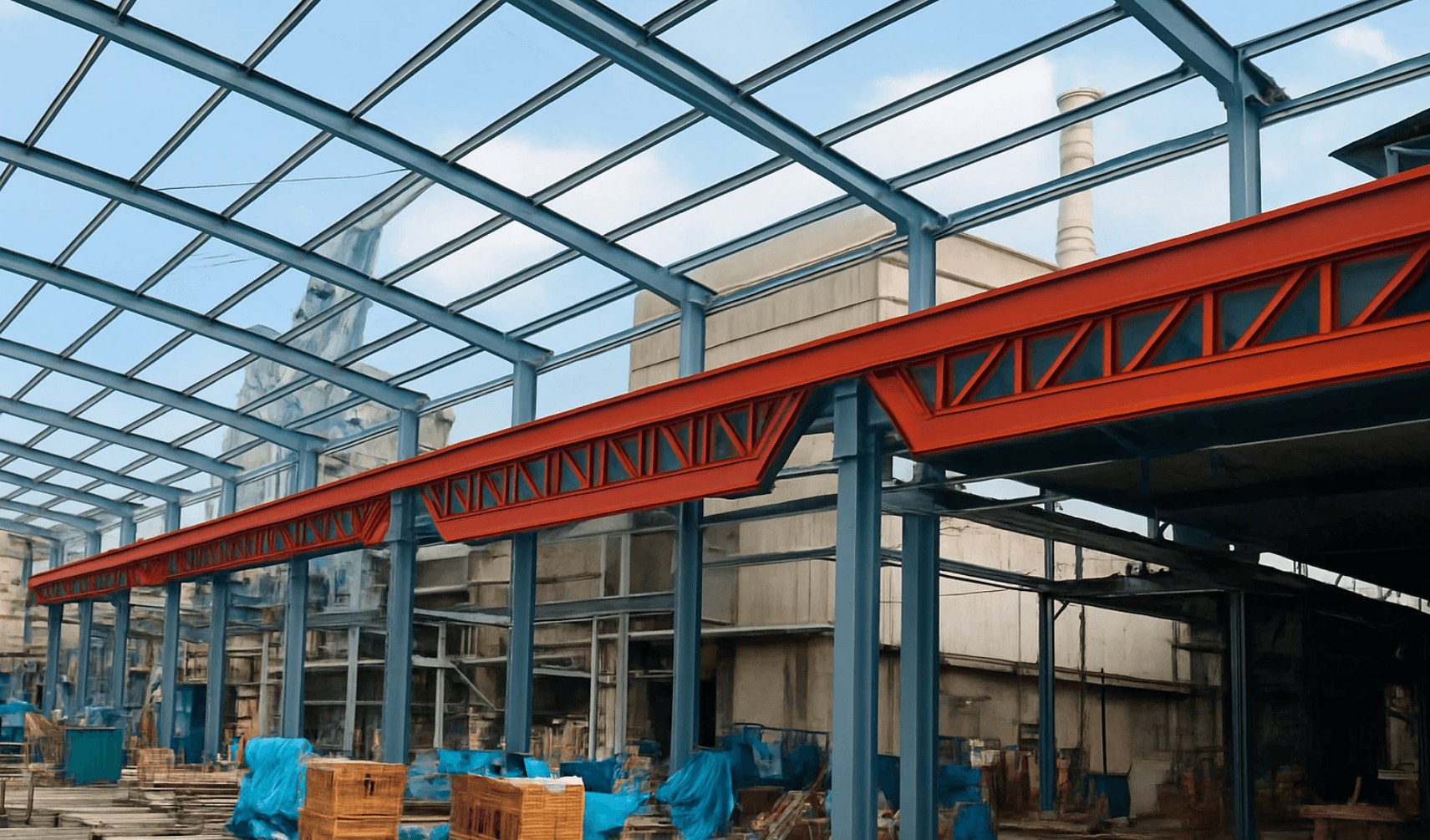

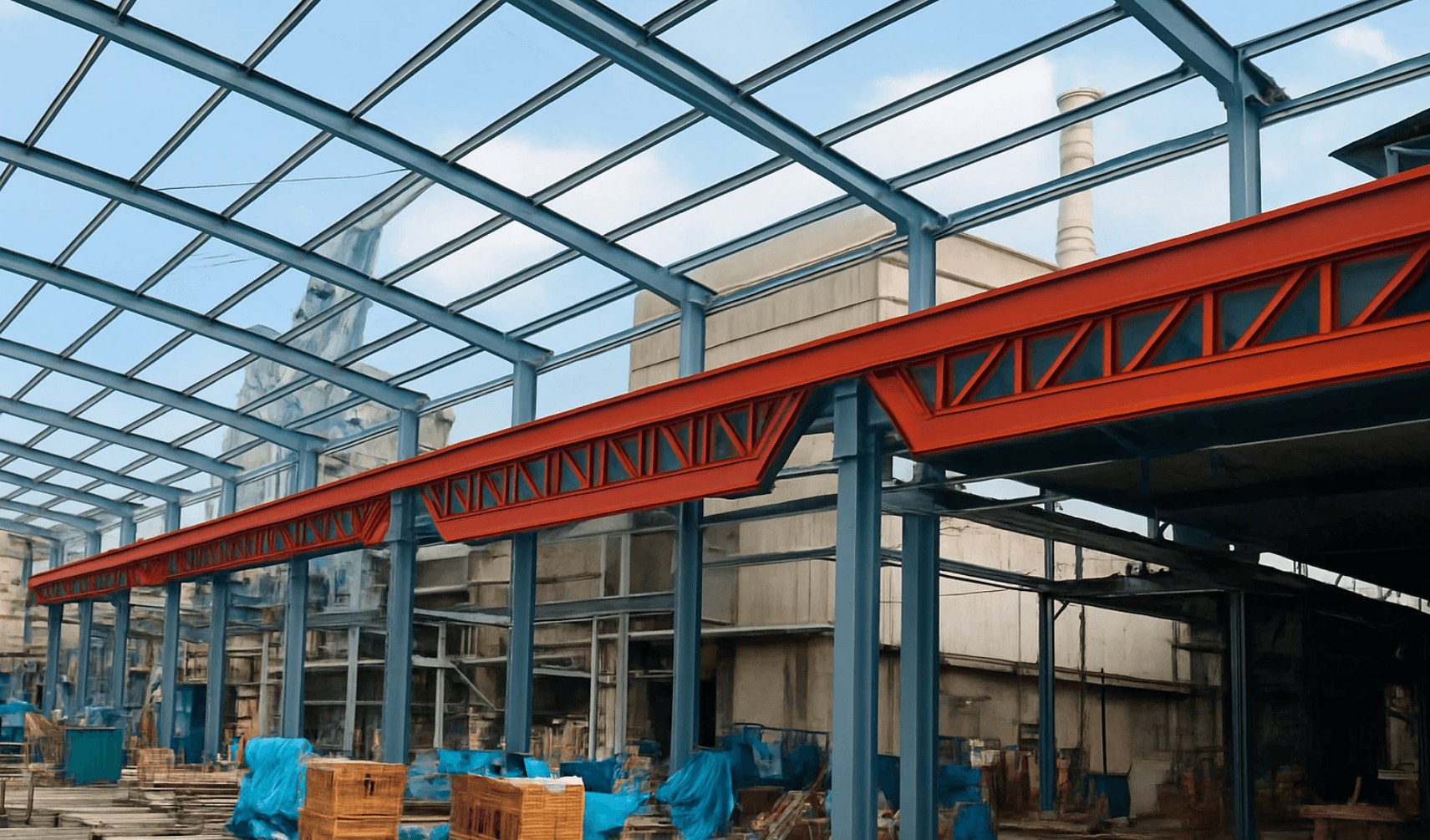

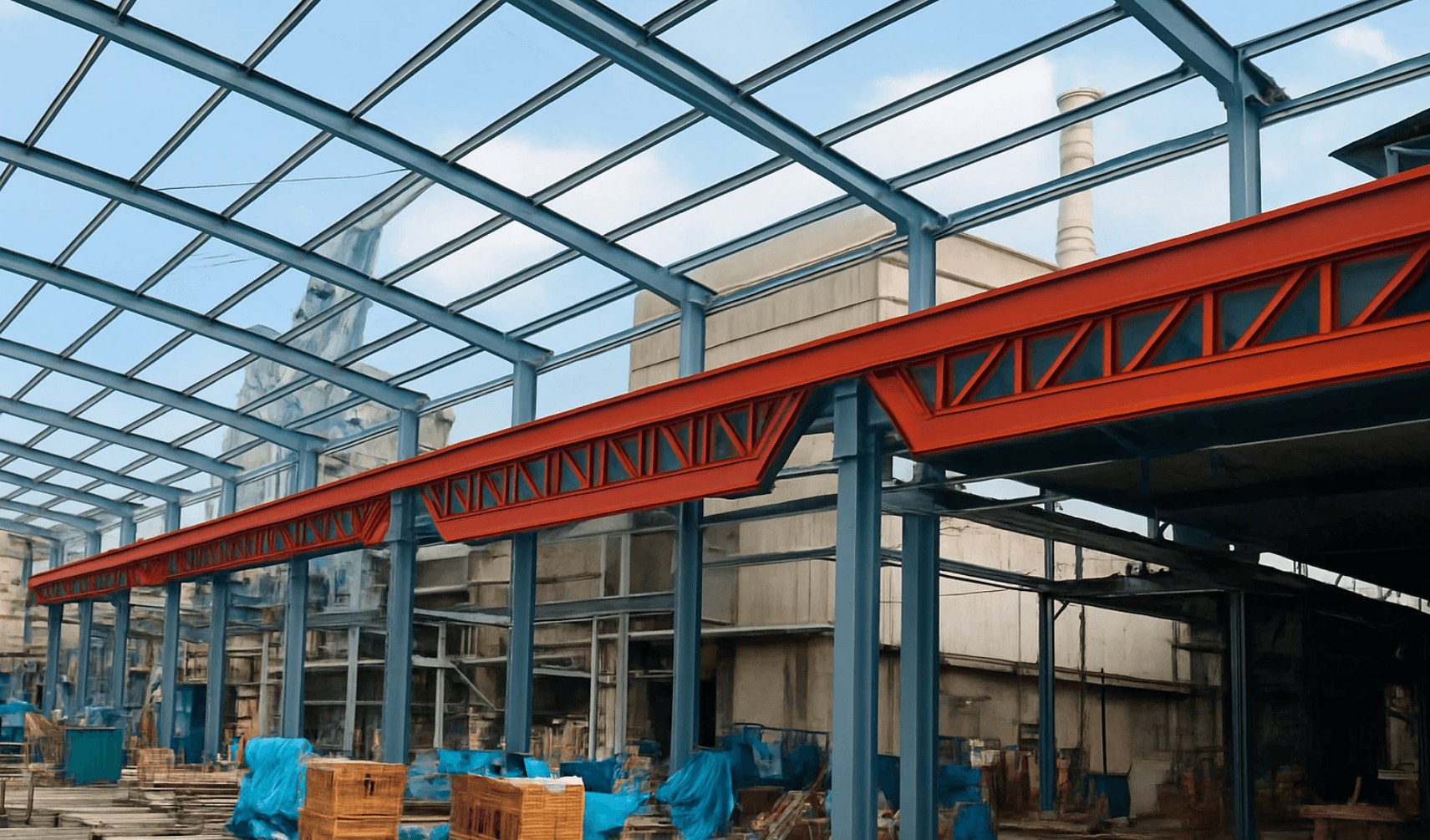

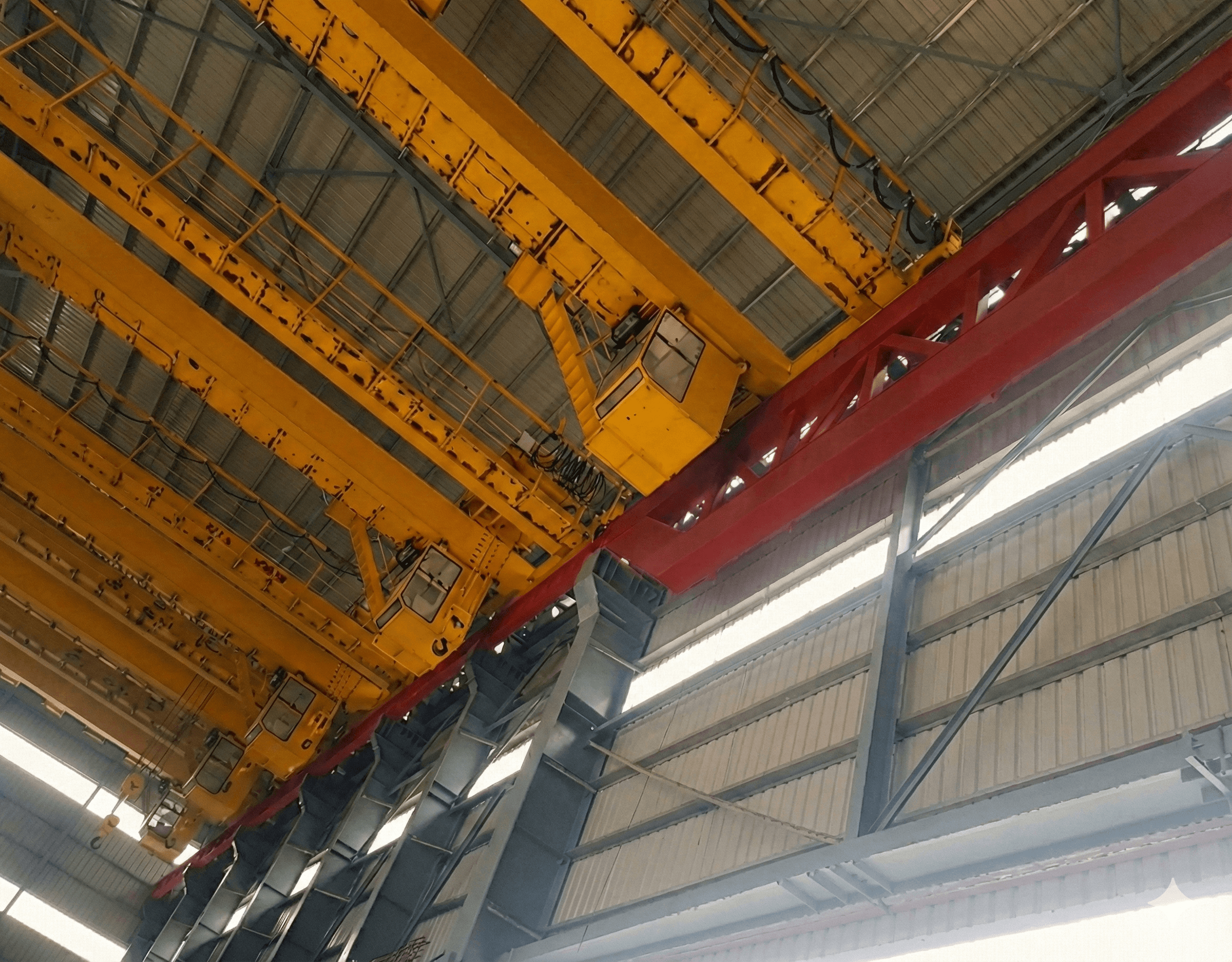

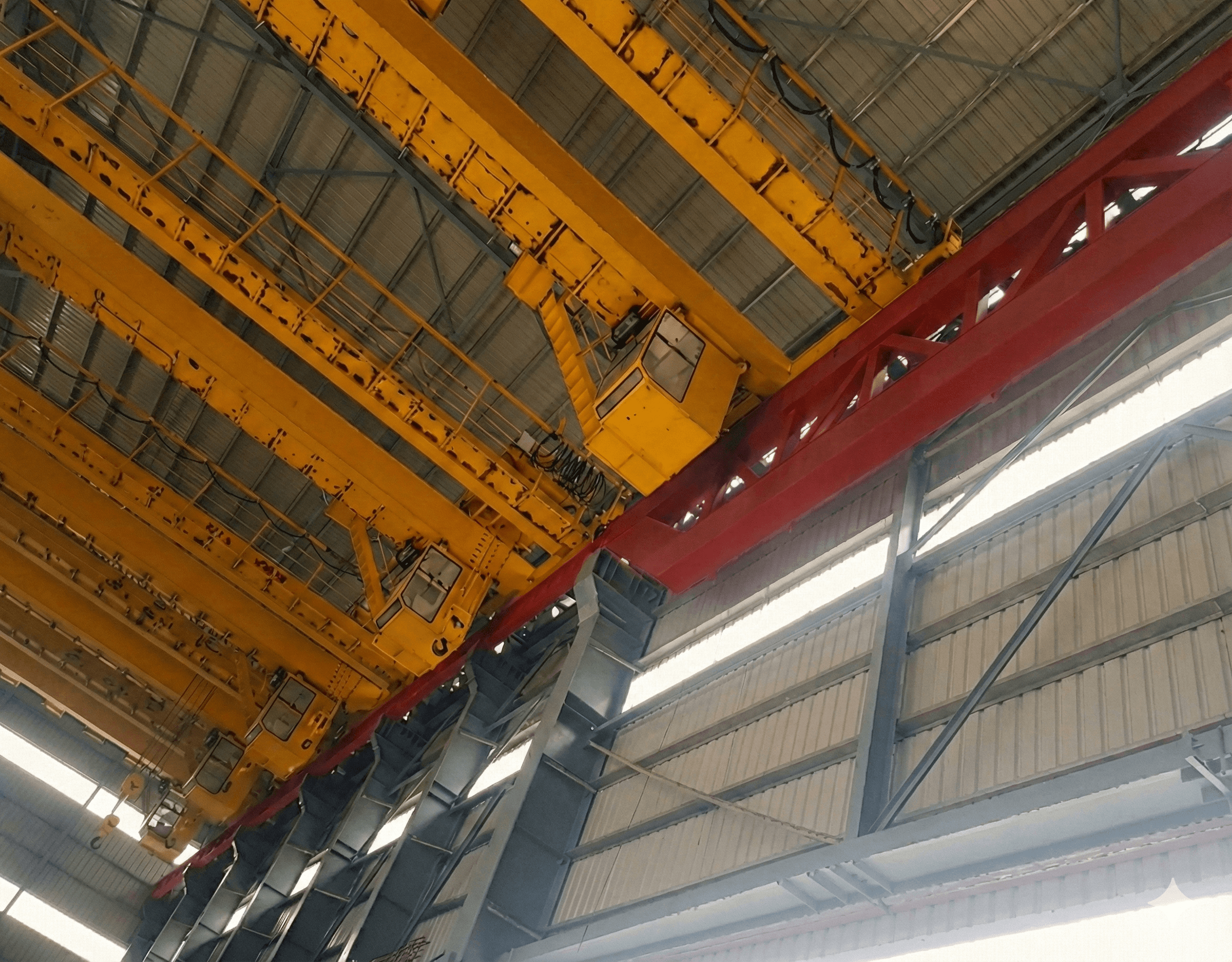

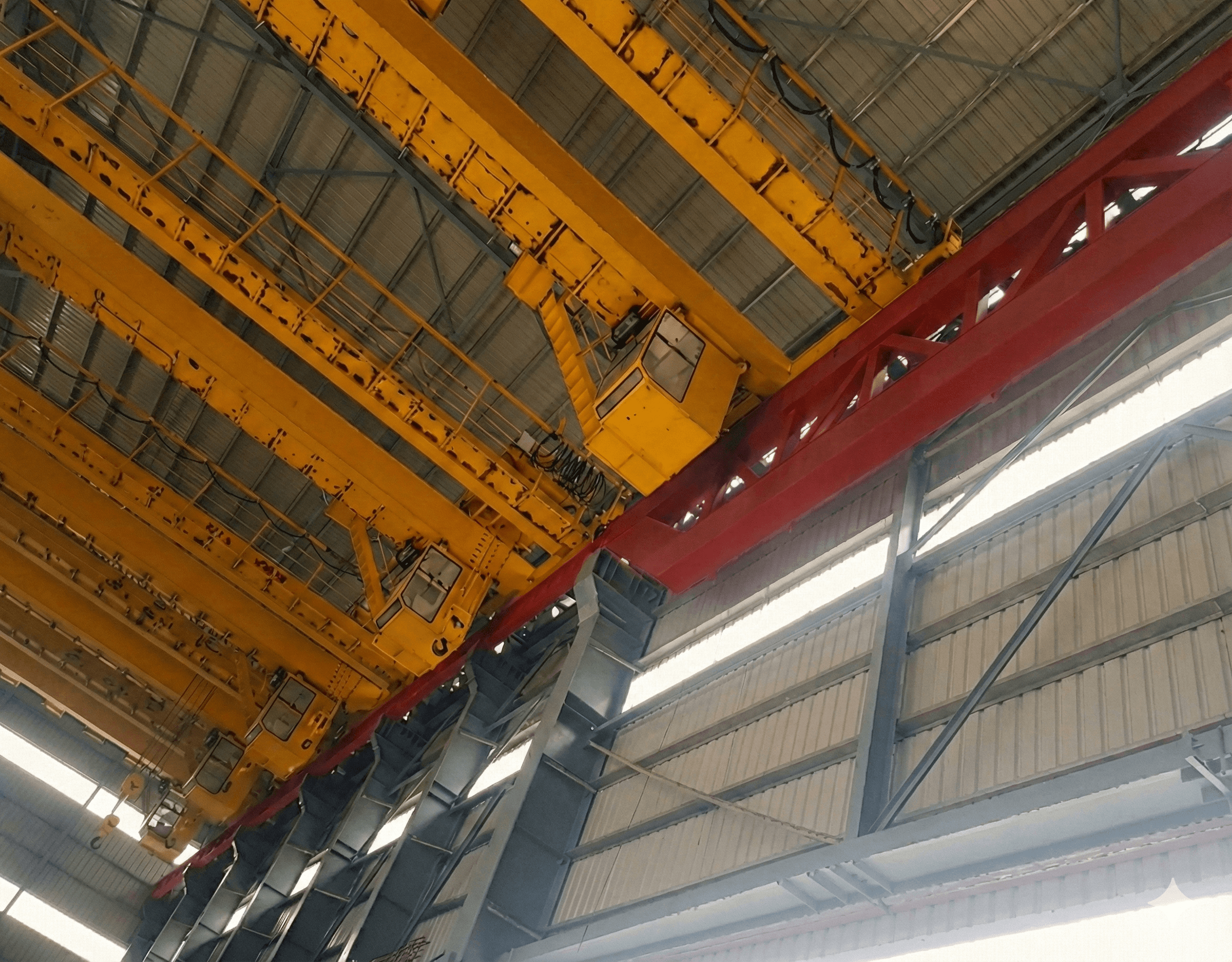

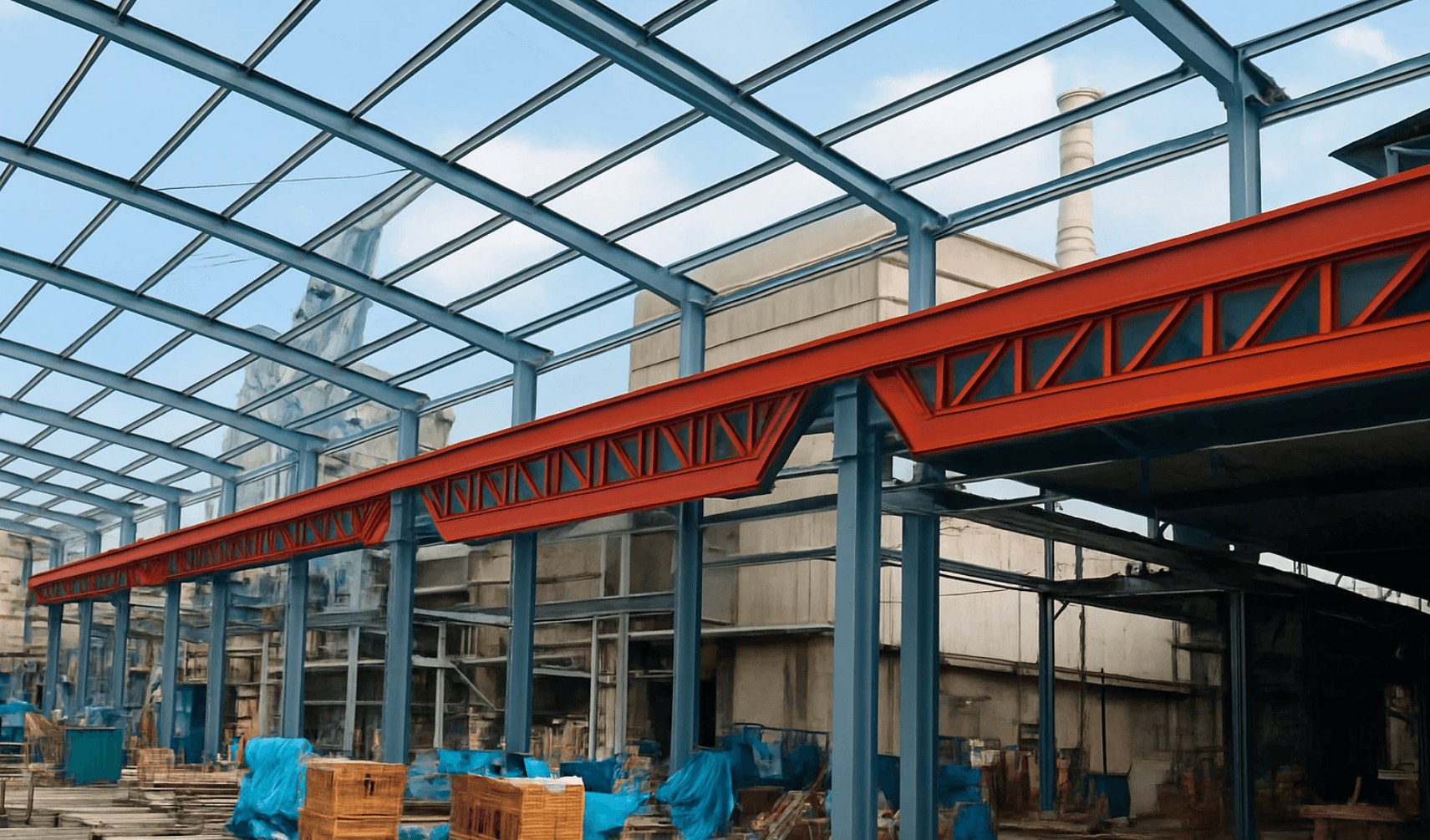

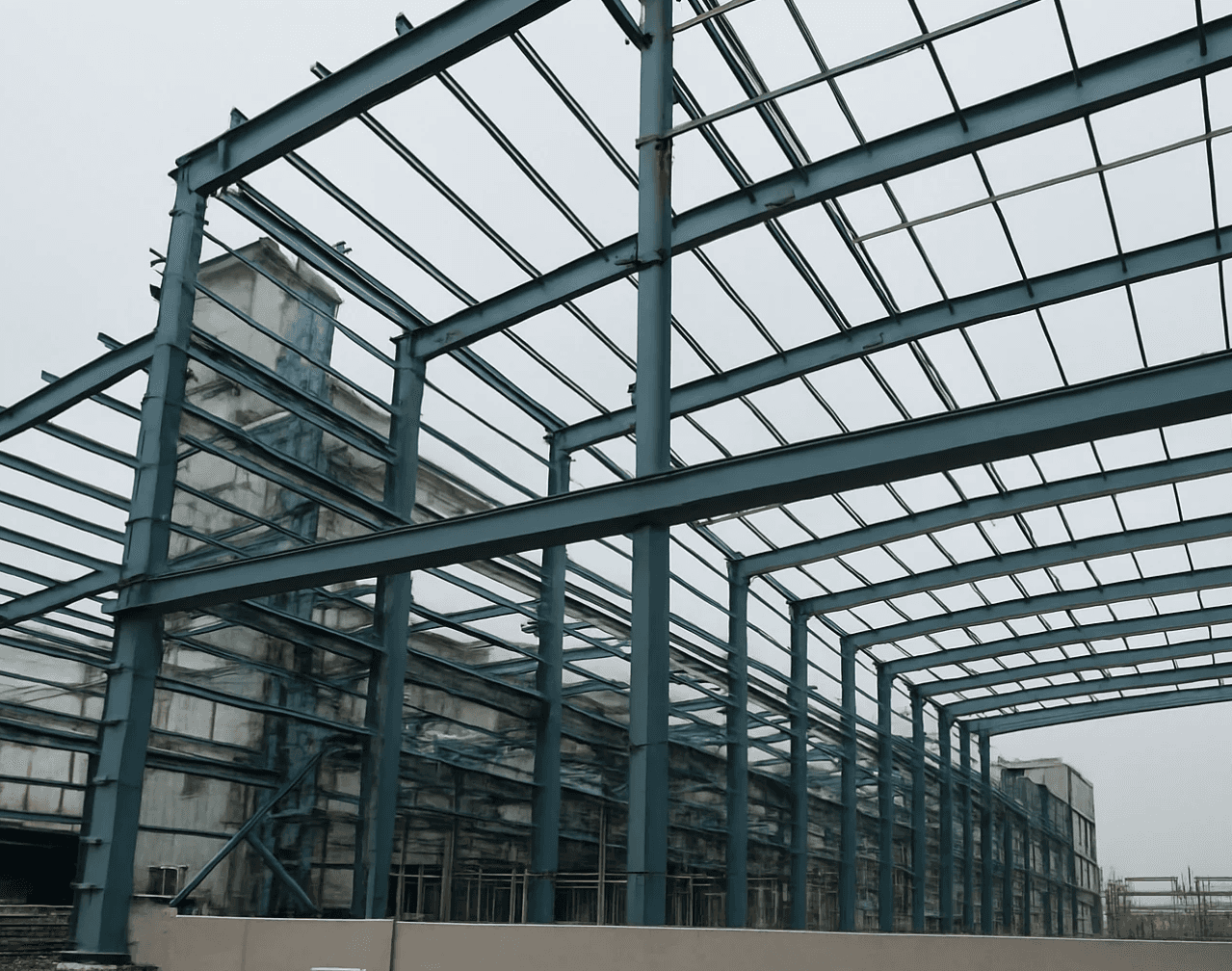

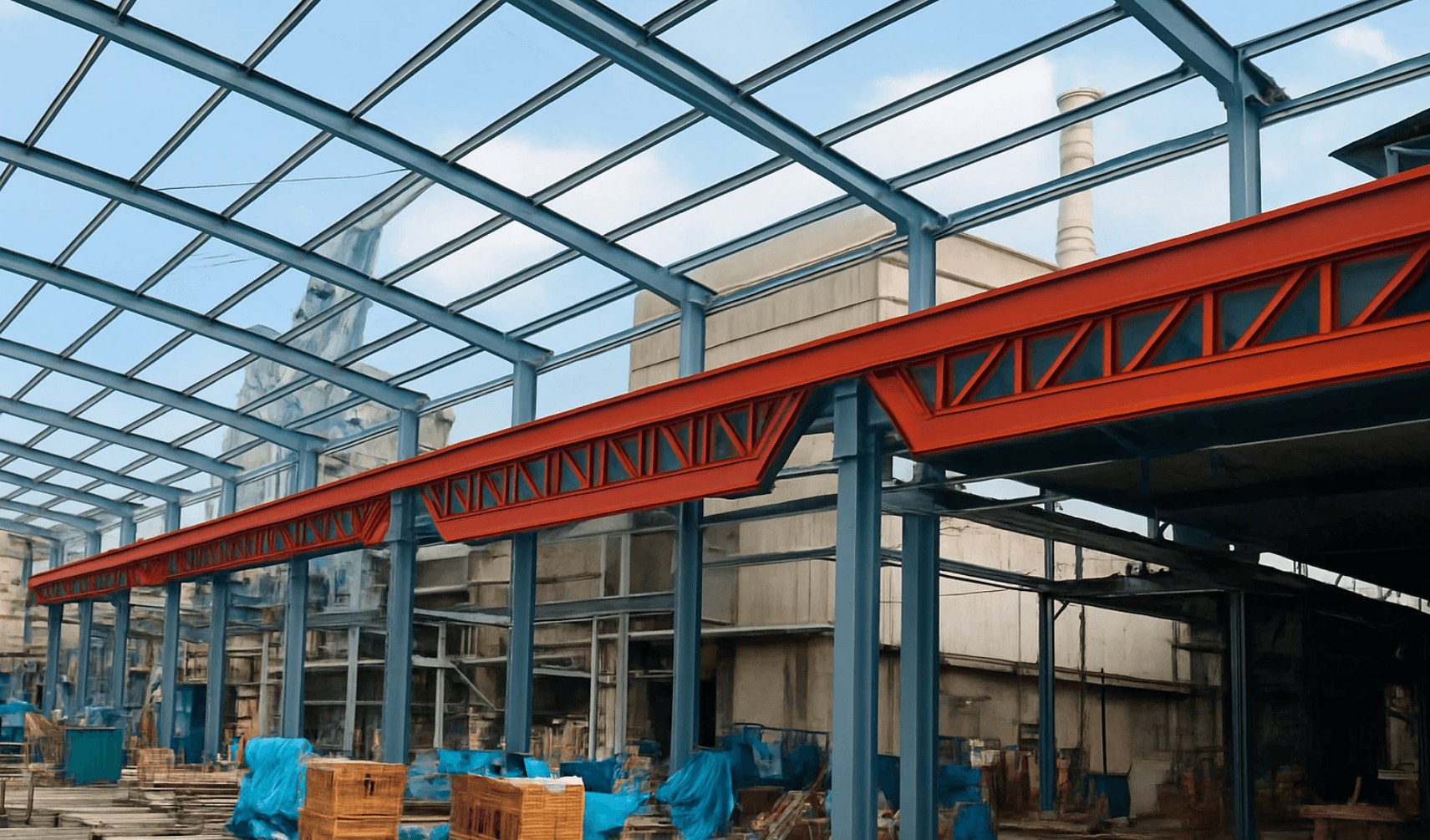

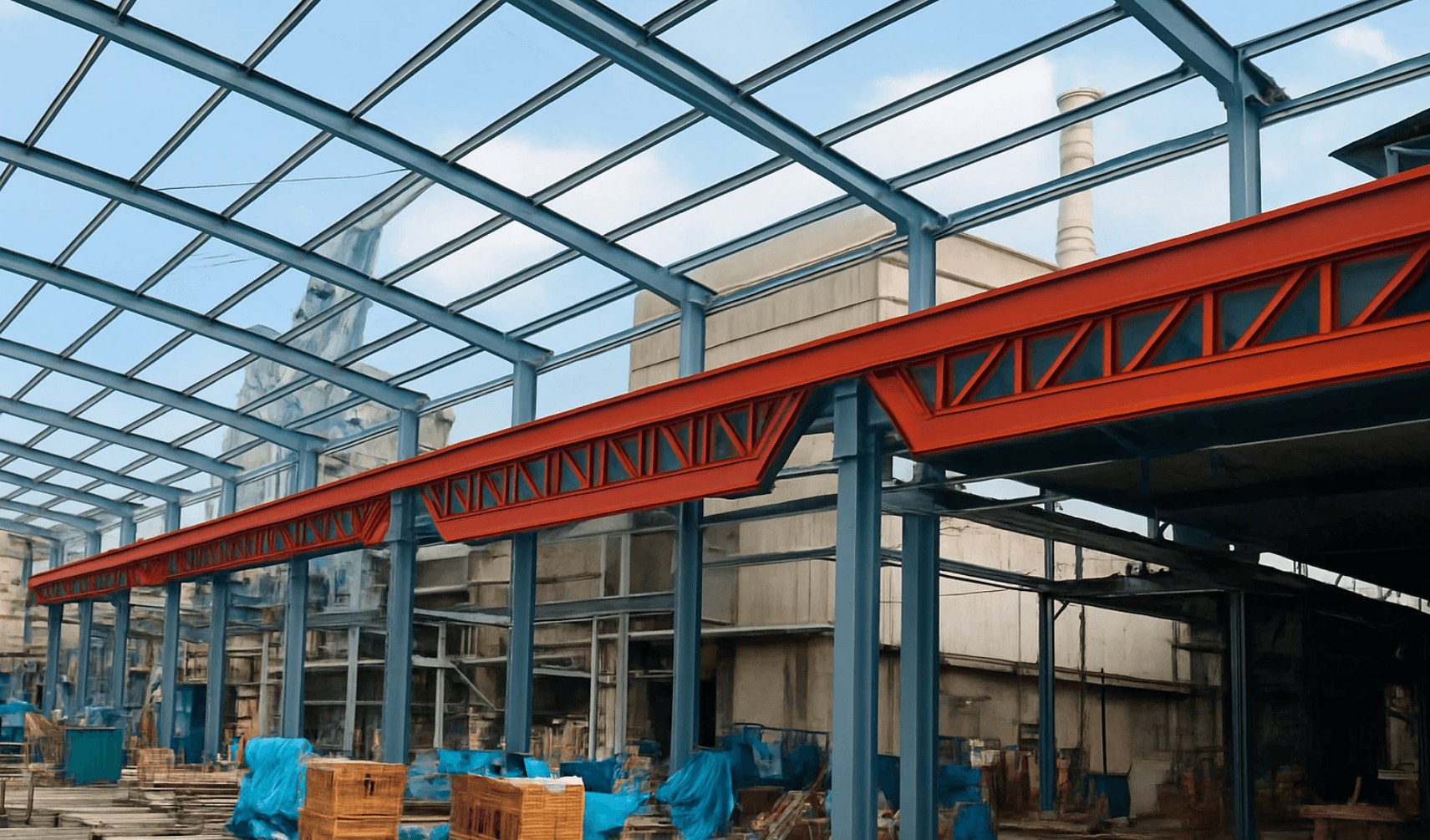

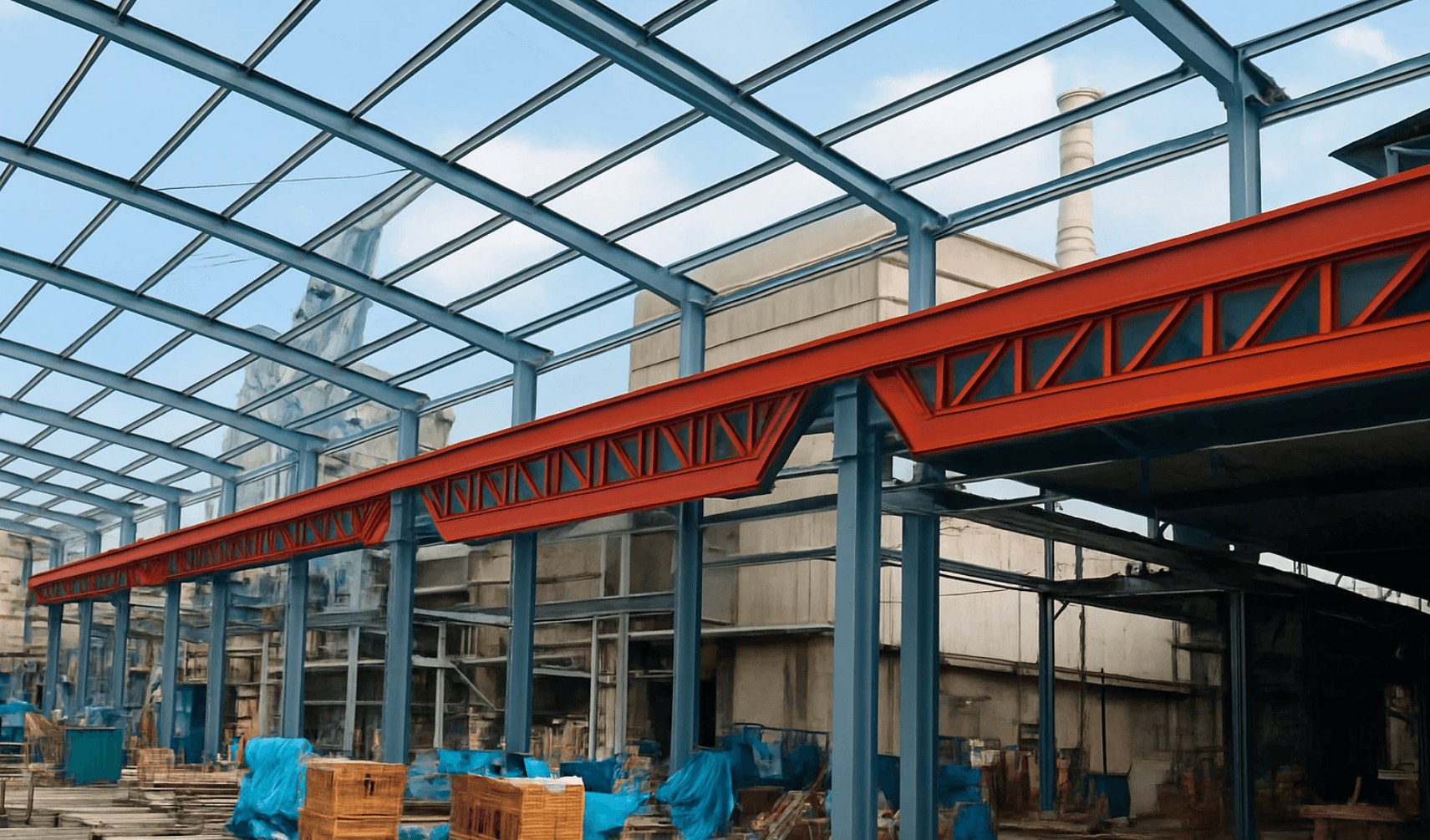

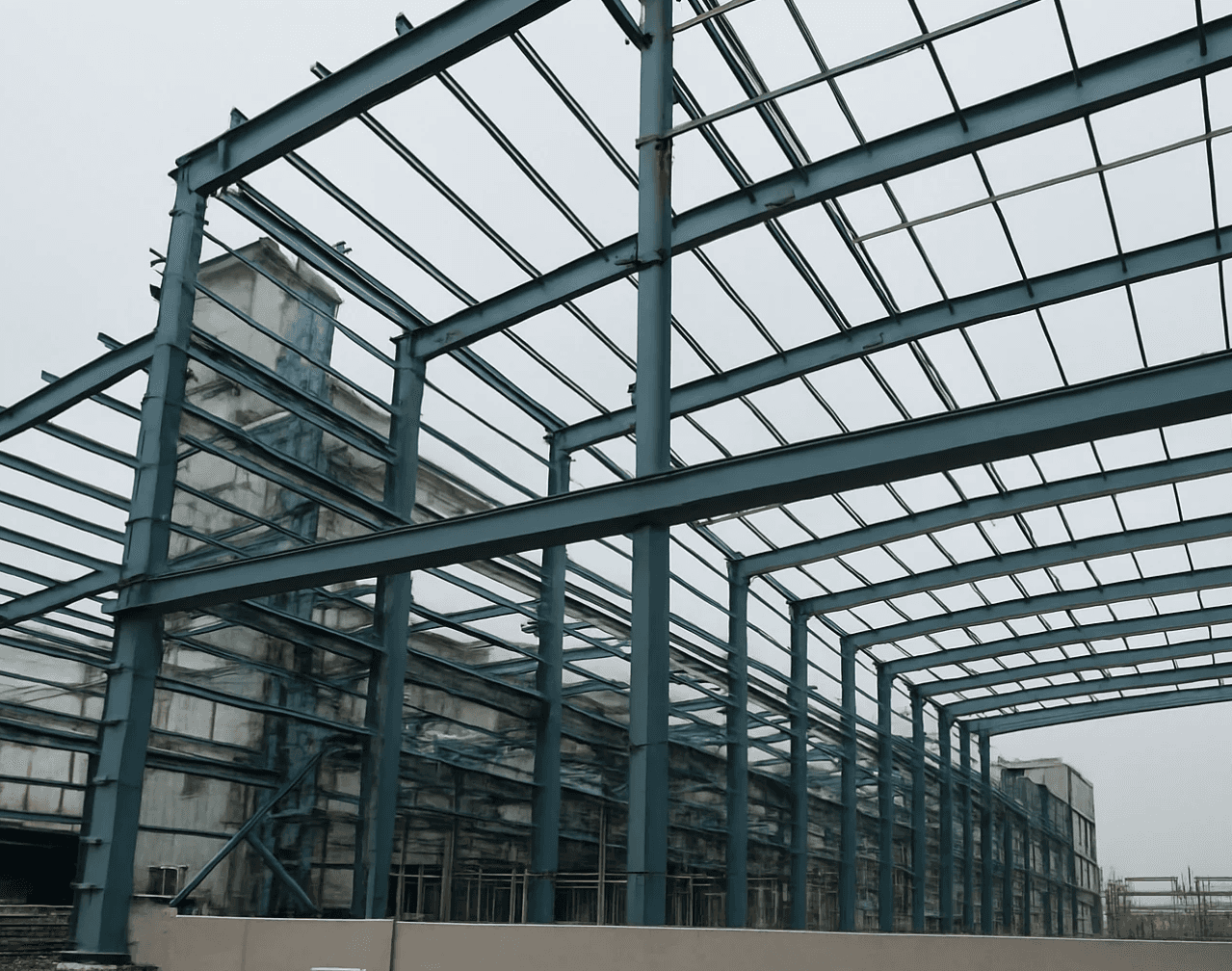

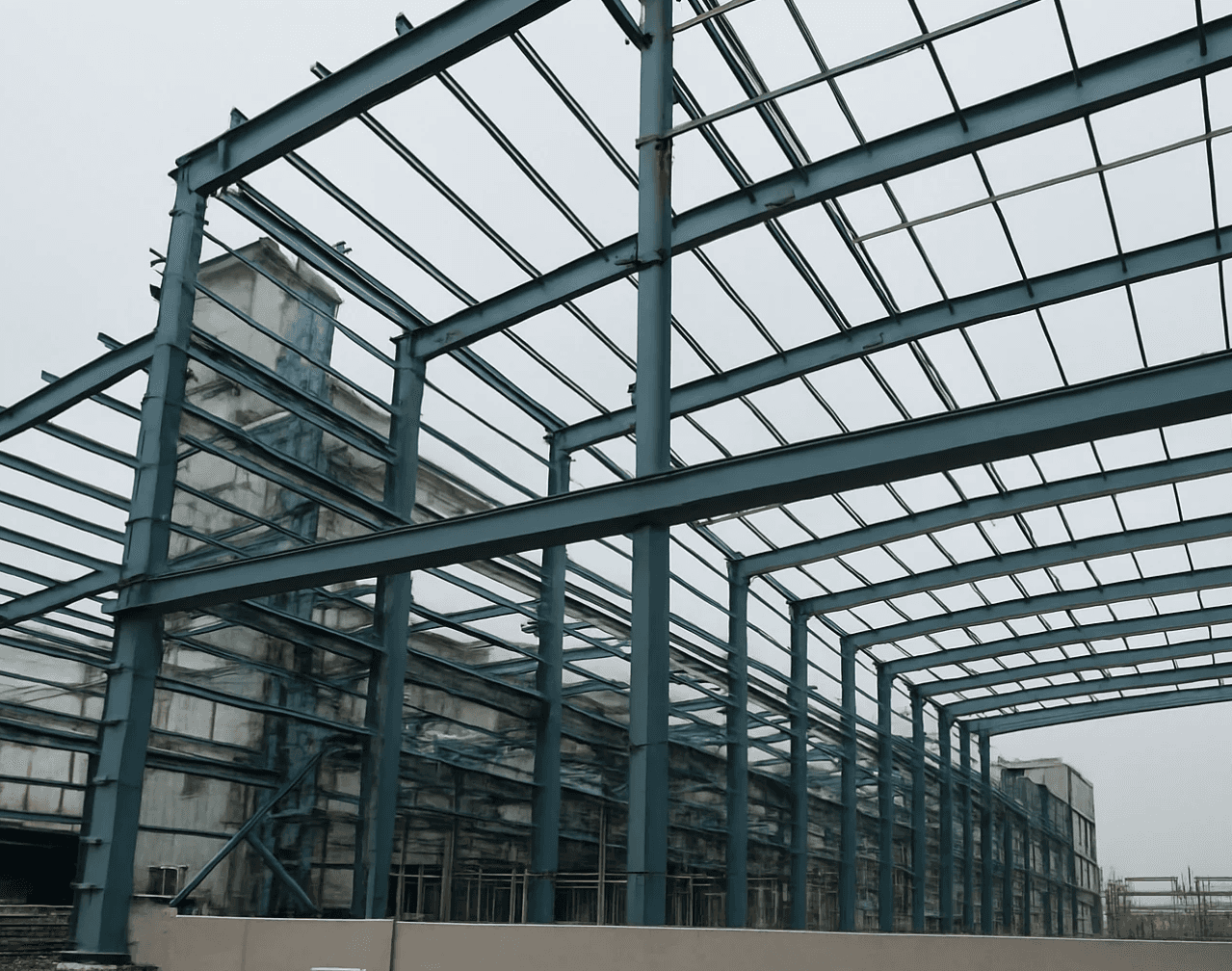

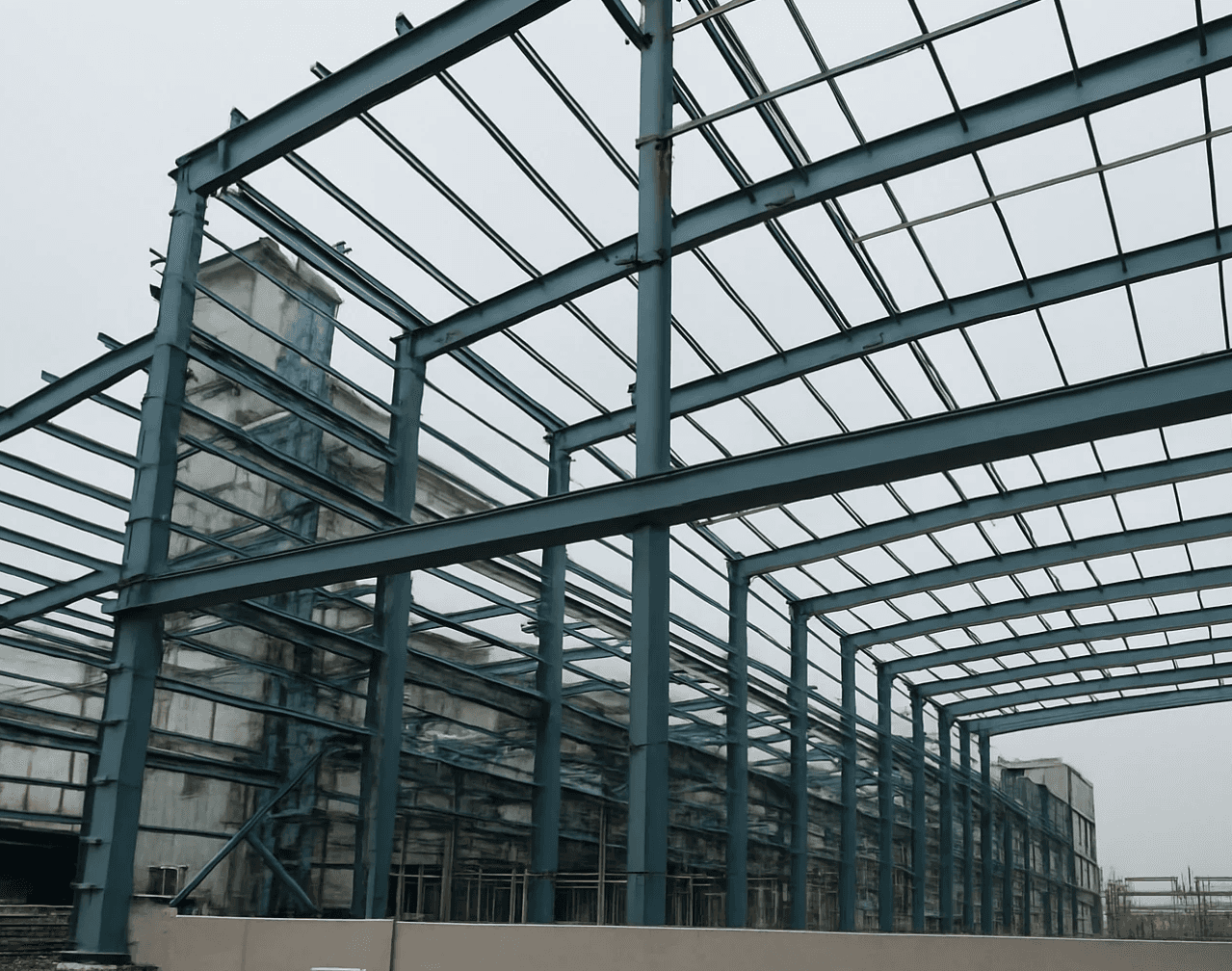

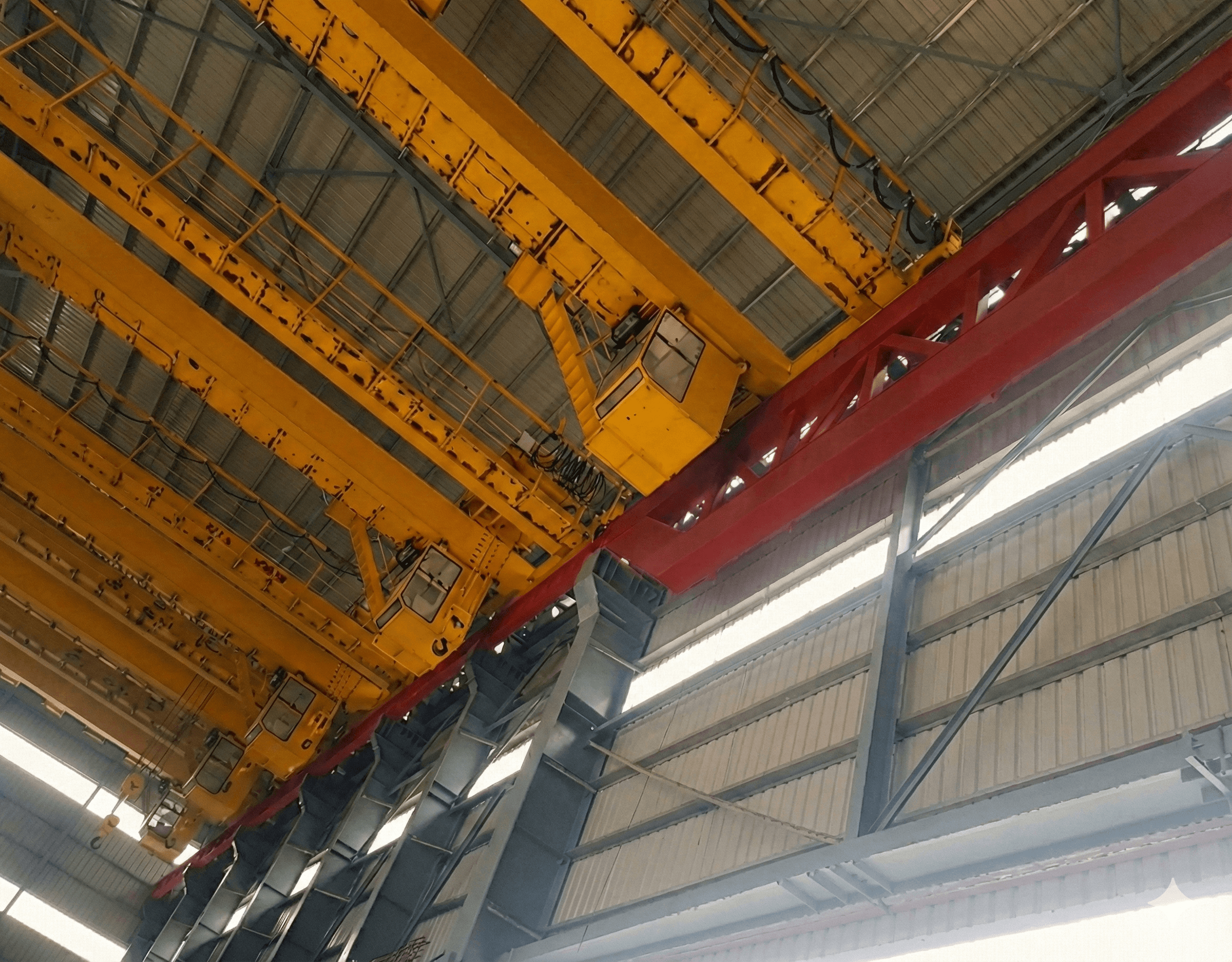

Lambda Engineering provided full structural and fabrication engineering for a large-span industrial steel structure designed to accommodate dual overhead cranes with rated capacities of 50 metric tons and 75 metric tons. The structure integrates heavy built-up steel members anchored over reinforced concrete pedestals and deep foundations to withstand both vertical and lateral crane loads.

Key Design Features

Structure Type: Steel portal frame with crane-supporting gantry girders.

Span Configuration: Approx. 25–30 m bay spacing, 18–20 m clear height.

Primary Members: Built-up I-sections for columns and rafters with end-plate bolted connections.

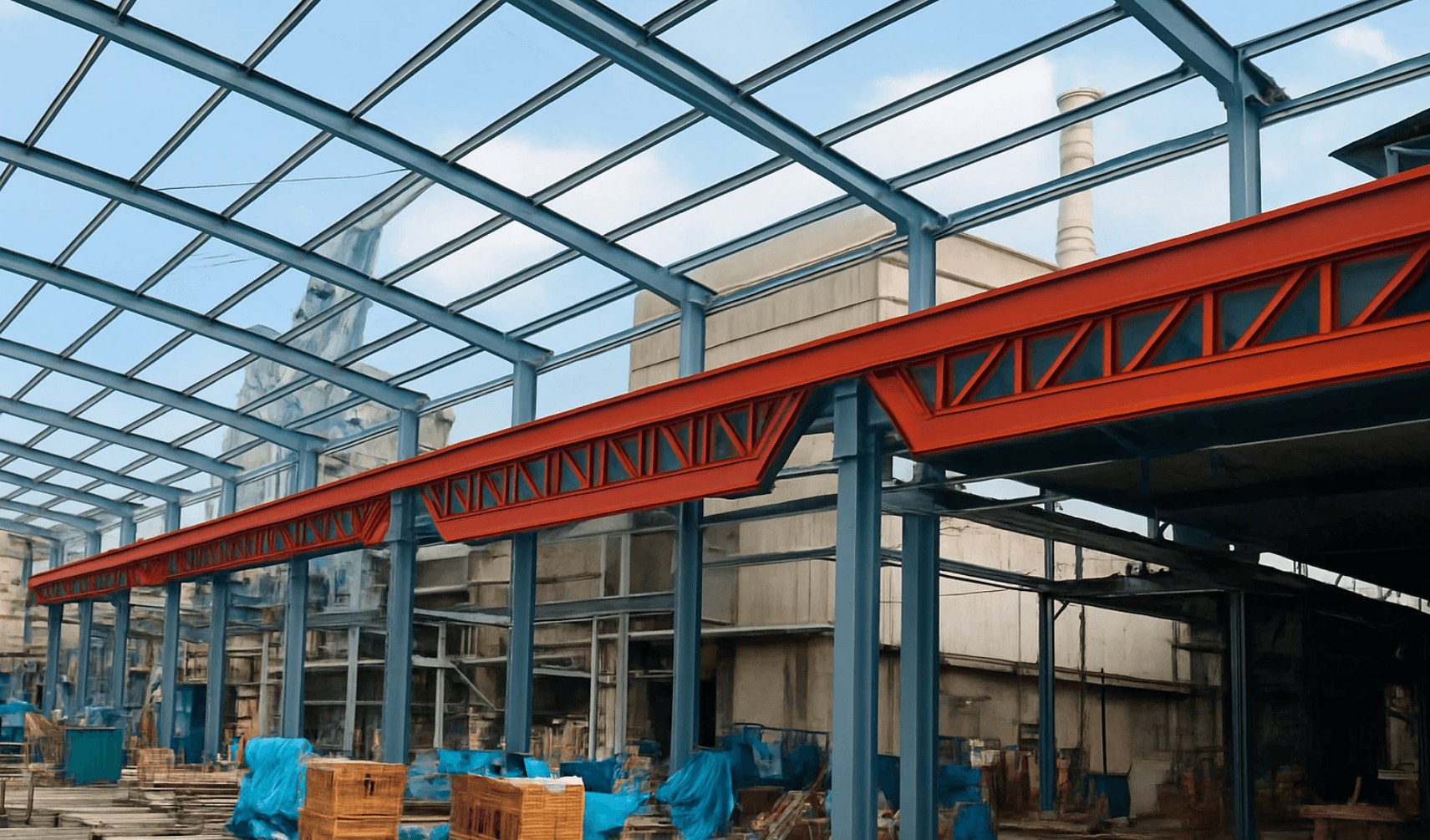

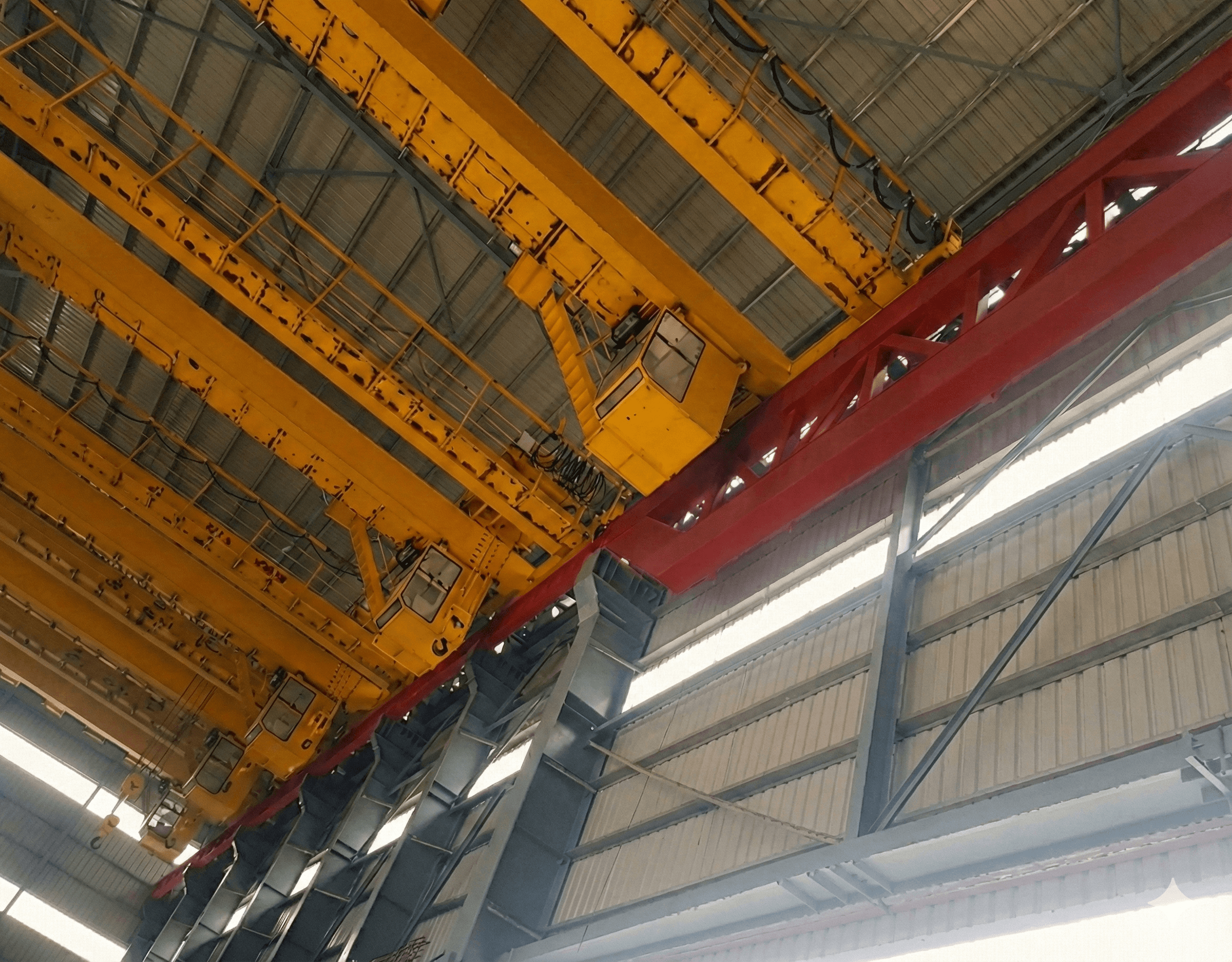

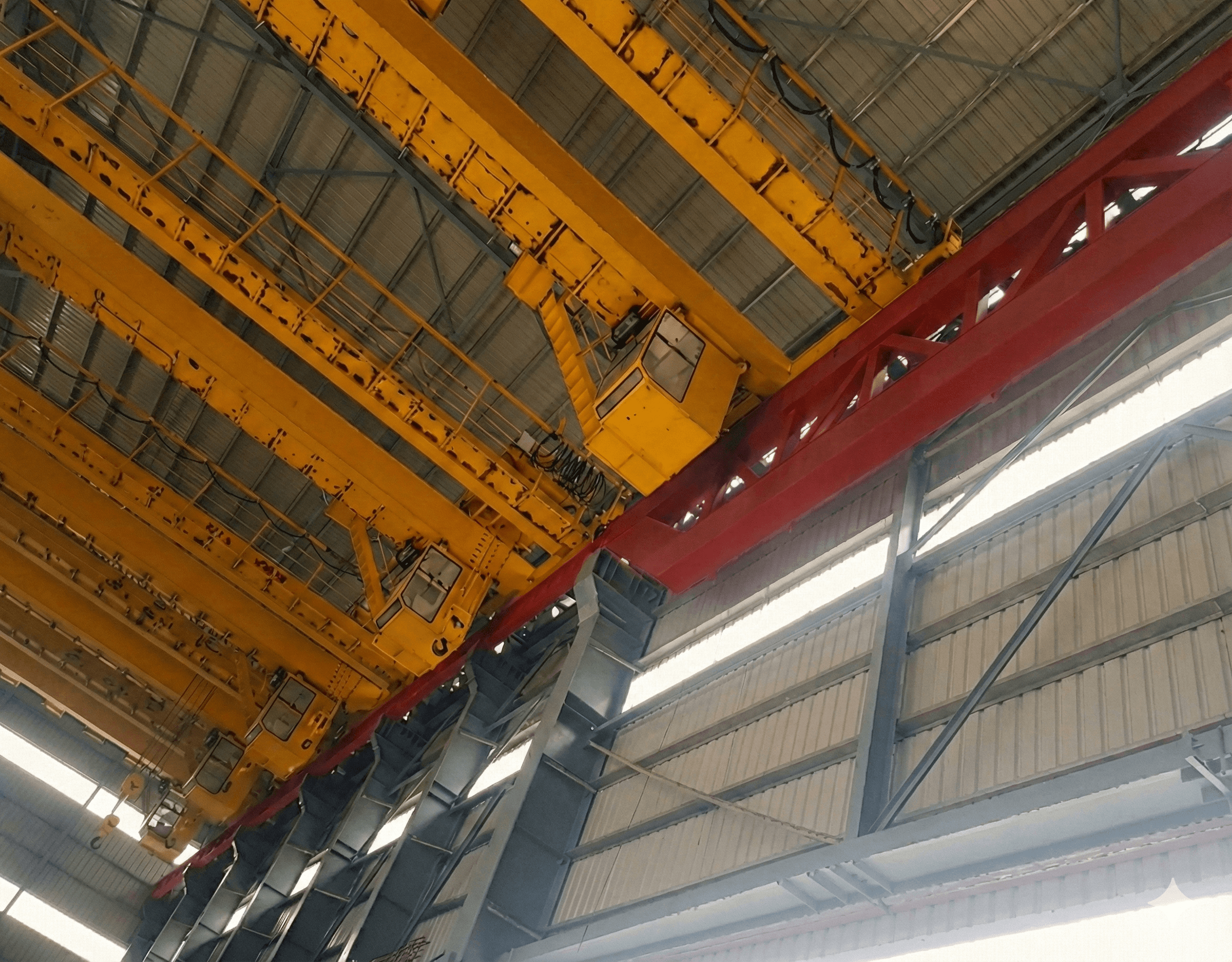

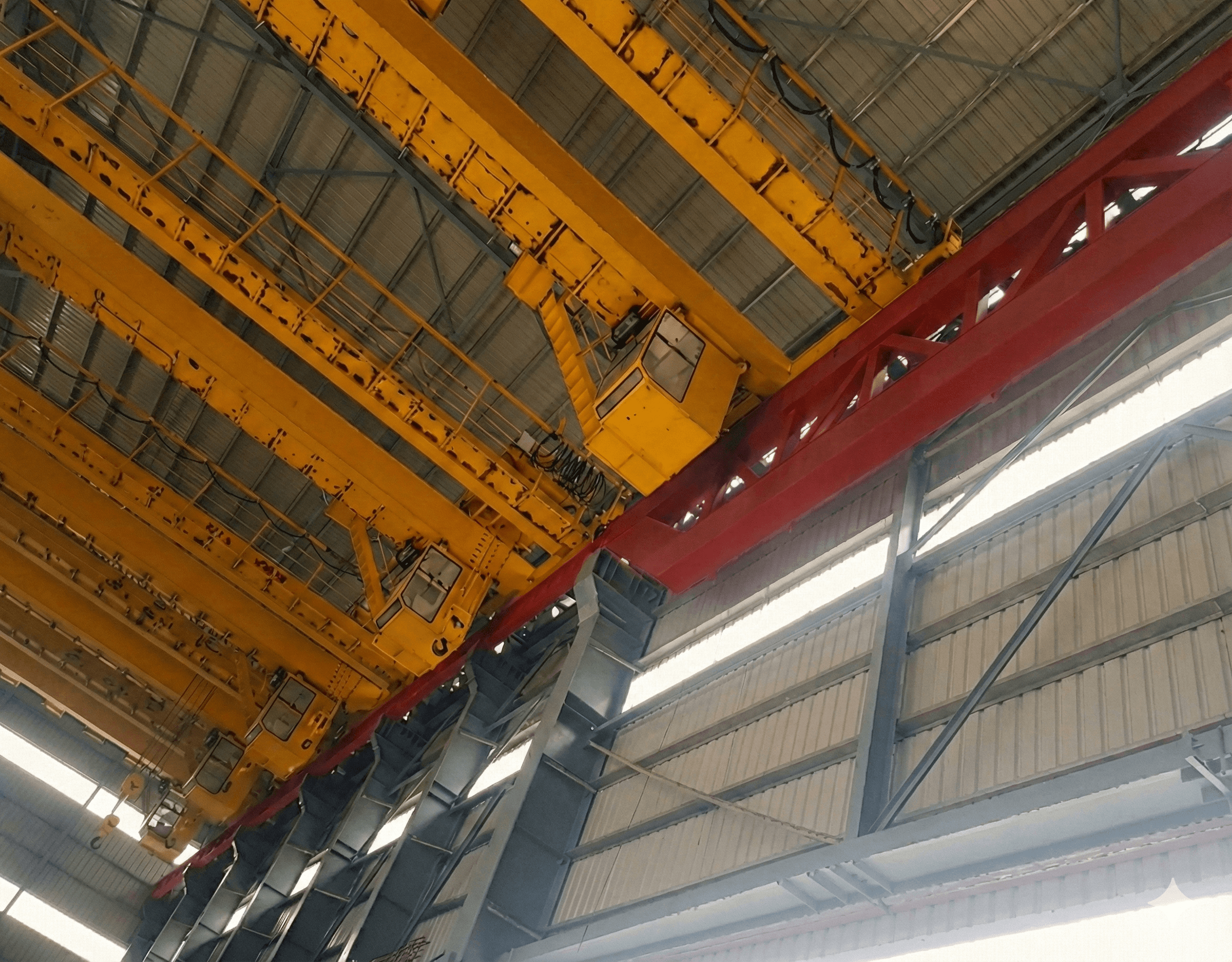

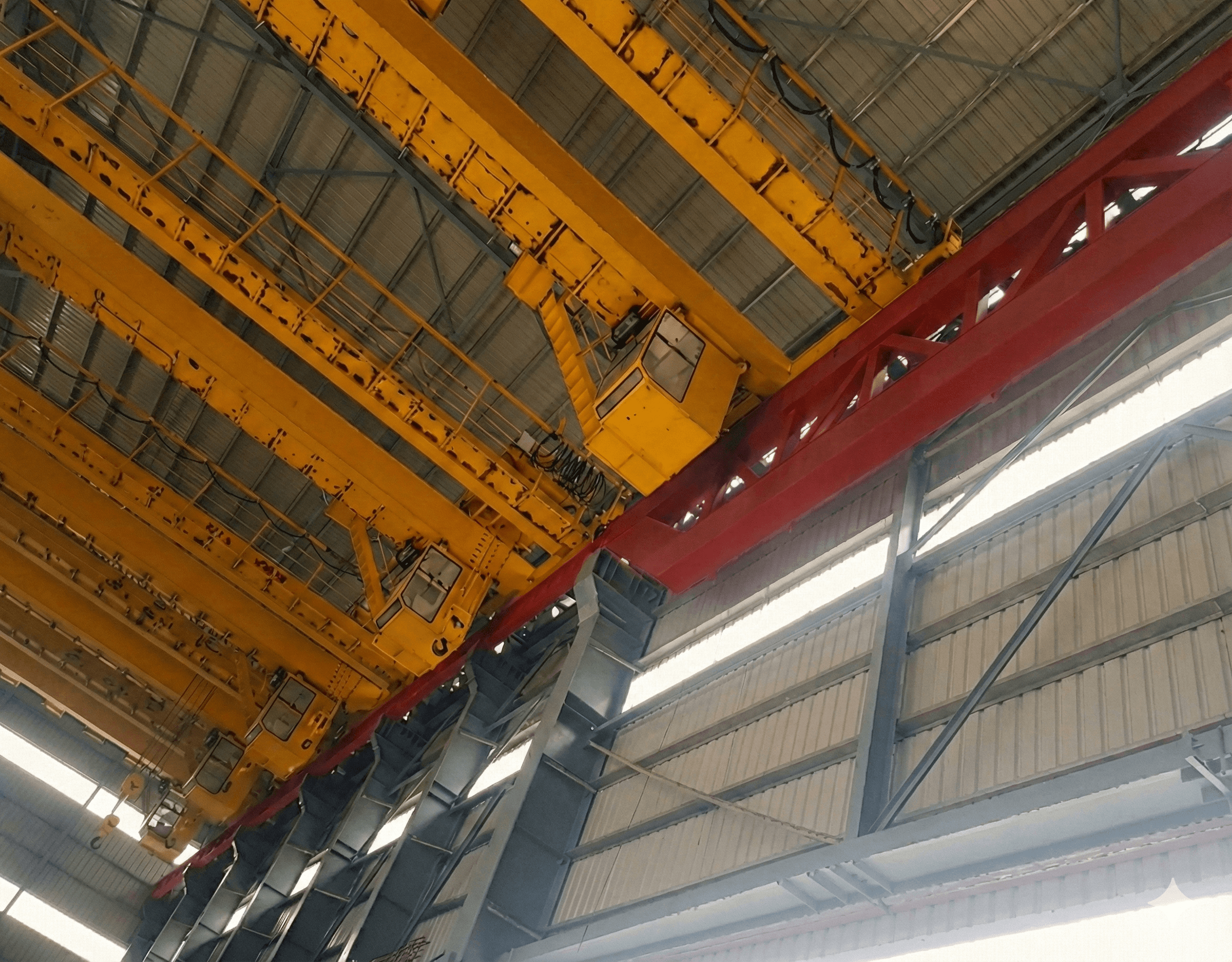

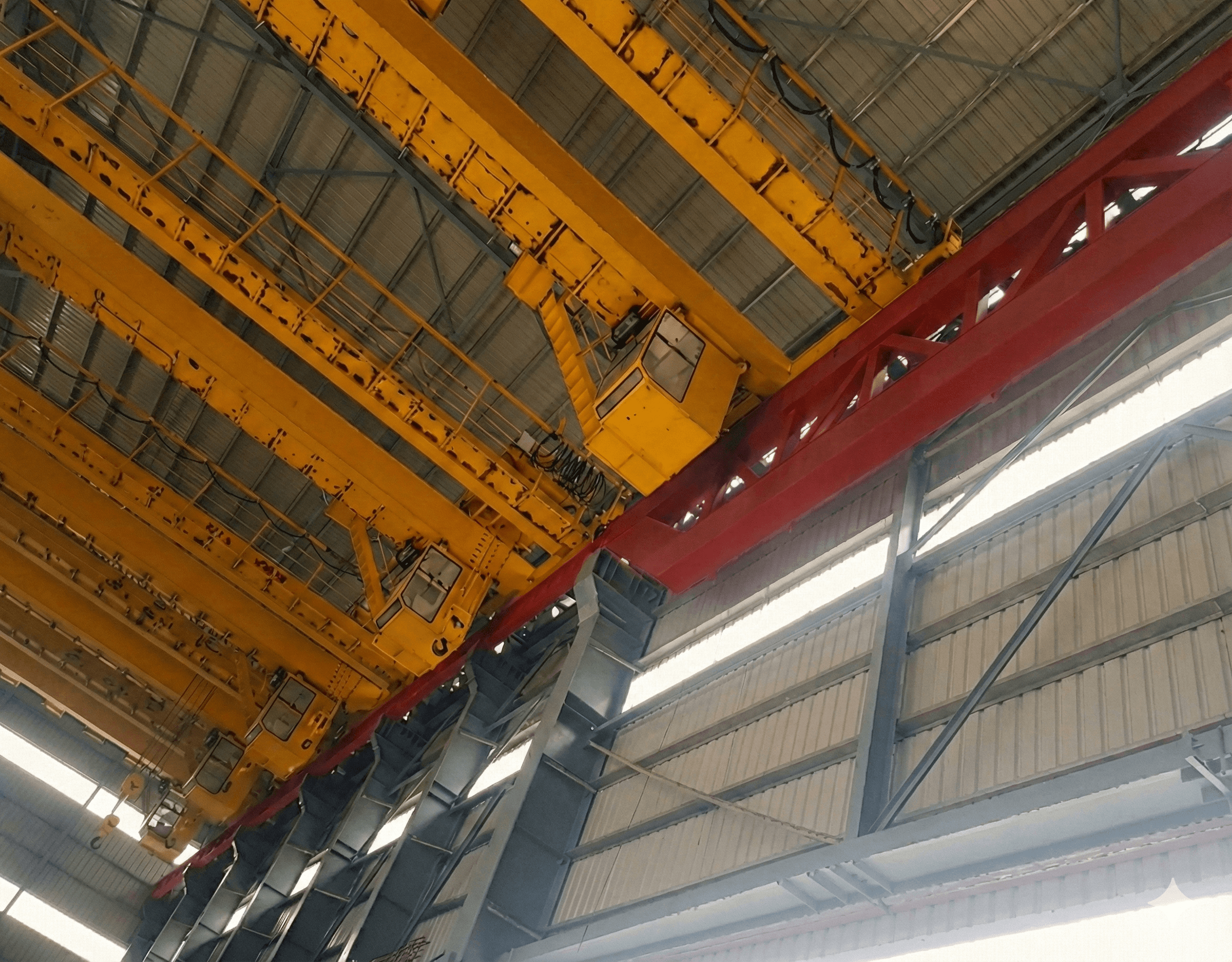

Gantry Girders: Custom lattice-type truss beams (painted red) designed for high load efficiency, supporting crane rails and wheel loads exceeding 350 kN per wheel.

Crane System: Two double-girder electric overhead traveling (EOT) cranes—50 MT and 75 MT—with integrated operator cabins and service platforms.

Foundation & Pedestals: Reinforced concrete grade beams and column pedestals engineered to absorb dynamic impact loads, surge forces, and lateral drift control.

Roof & Wall System: Cold-formed Z-purlins and C-girts supporting profiled sheeting; roof bracing to resist wind uplift and sway.

Lateral Stability: Full system of X-bracing and portal action with moment-resisting connections.

Engineering Highlights

Designed per AISC 360-16 and ACI 318-19 standards, with crane load verification per CMAA-70 Class D duty cycle.

Conducted 3D structural analysis (STAAD / SAP2000) for load combinations including impact, wind, and seismic actions.

Fabrication drawings and connection details were optimized for shop welding and on-site bolting for quick assembly.

Coordinated with MEP and crane installation teams to ensure alignment tolerances within ±3 mm along the runway.

Result

The resulting shed achieved exceptional structural stability and operational reliability under continuous crane duty cycles—an example of precision steel engineering and multidisciplinary coordination.

Latest Projects

Pre-Eng. Buildings

Cranes Shed

Cranes Shed

Cranes Shed

Heavy-Duty Industrial Shed for 50 MT & 75 MT Crane System

Heavy-Duty Industrial Shed for 50 MT & 75 MT Crane System

Heavy-Duty Industrial Shed for 50 MT & 75 MT Crane System

Year

2025

Year

2025

Year

2025

Industry

Construction / Steel Fabrication

Industry

Construction / Steel Fabrication

Industry

Construction / Steel Fabrication

Project Duration

4 weeks

Project Duration

4 weeks

Project Duration

4 weeks

Intro

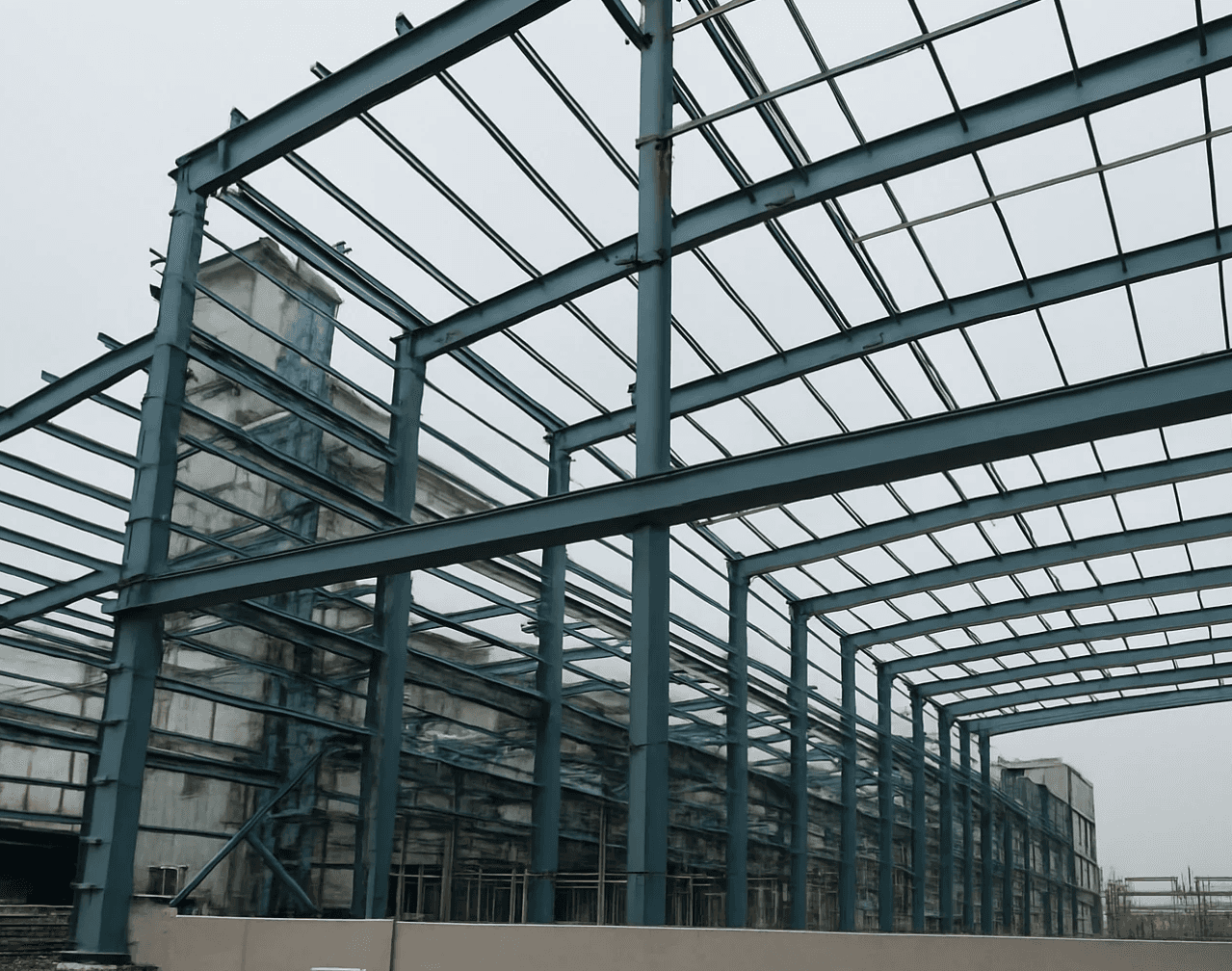

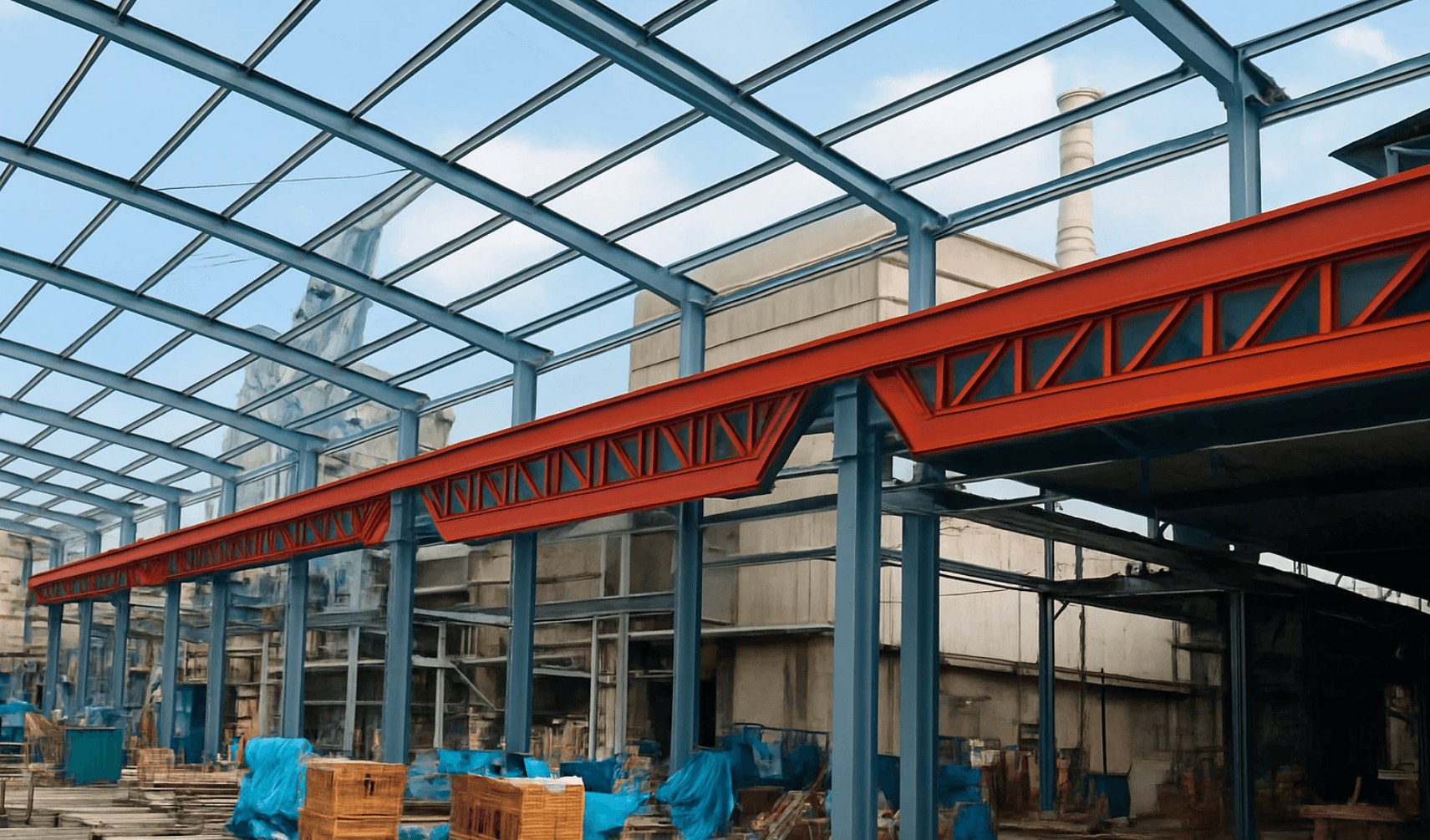

Lambda Engineering provided full structural and fabrication engineering for a large-span industrial steel structure designed to accommodate dual overhead cranes with rated capacities of 50 metric tons and 75 metric tons. The structure integrates heavy built-up steel members anchored over reinforced concrete pedestals and deep foundations to withstand both vertical and lateral crane loads.

Key Design Features

Structure Type: Steel portal frame with crane-supporting gantry girders.

Span Configuration: Approx. 25–30 m bay spacing, 18–20 m clear height.

Primary Members: Built-up I-sections for columns and rafters with end-plate bolted connections.

Gantry Girders: Custom lattice-type truss beams (painted red) designed for high load efficiency, supporting crane rails and wheel loads exceeding 350 kN per wheel.

Crane System: Two double-girder electric overhead traveling (EOT) cranes—50 MT and 75 MT—with integrated operator cabins and service platforms.

Foundation & Pedestals: Reinforced concrete grade beams and column pedestals engineered to absorb dynamic impact loads, surge forces, and lateral drift control.

Roof & Wall System: Cold-formed Z-purlins and C-girts supporting profiled sheeting; roof bracing to resist wind uplift and sway.

Lateral Stability: Full system of X-bracing and portal action with moment-resisting connections.

Engineering Highlights

Designed per AISC 360-16 and ACI 318-19 standards, with crane load verification per CMAA-70 Class D duty cycle.

Conducted 3D structural analysis (STAAD / SAP2000) for load combinations including impact, wind, and seismic actions.

Fabrication drawings and connection details were optimized for shop welding and on-site bolting for quick assembly.

Coordinated with MEP and crane installation teams to ensure alignment tolerances within ±3 mm along the runway.

Result

The resulting shed achieved exceptional structural stability and operational reliability under continuous crane duty cycles—an example of precision steel engineering and multidisciplinary coordination.

Latest Projects

Pre-Eng. Buildings

Cranes Shed

Cranes Shed

Cranes Shed

Heavy-Duty Industrial Shed for 50 MT & 75 MT Crane System

Heavy-Duty Industrial Shed for 50 MT & 75 MT Crane System

Heavy-Duty Industrial Shed for 50 MT & 75 MT Crane System

Year

2025

Year

2025

Year

2025

Industry

Construction / Steel Fabrication

Industry

Construction / Steel Fabrication

Industry

Construction / Steel Fabrication

Project Duration

4 weeks

Project Duration

4 weeks

Project Duration

4 weeks

Intro

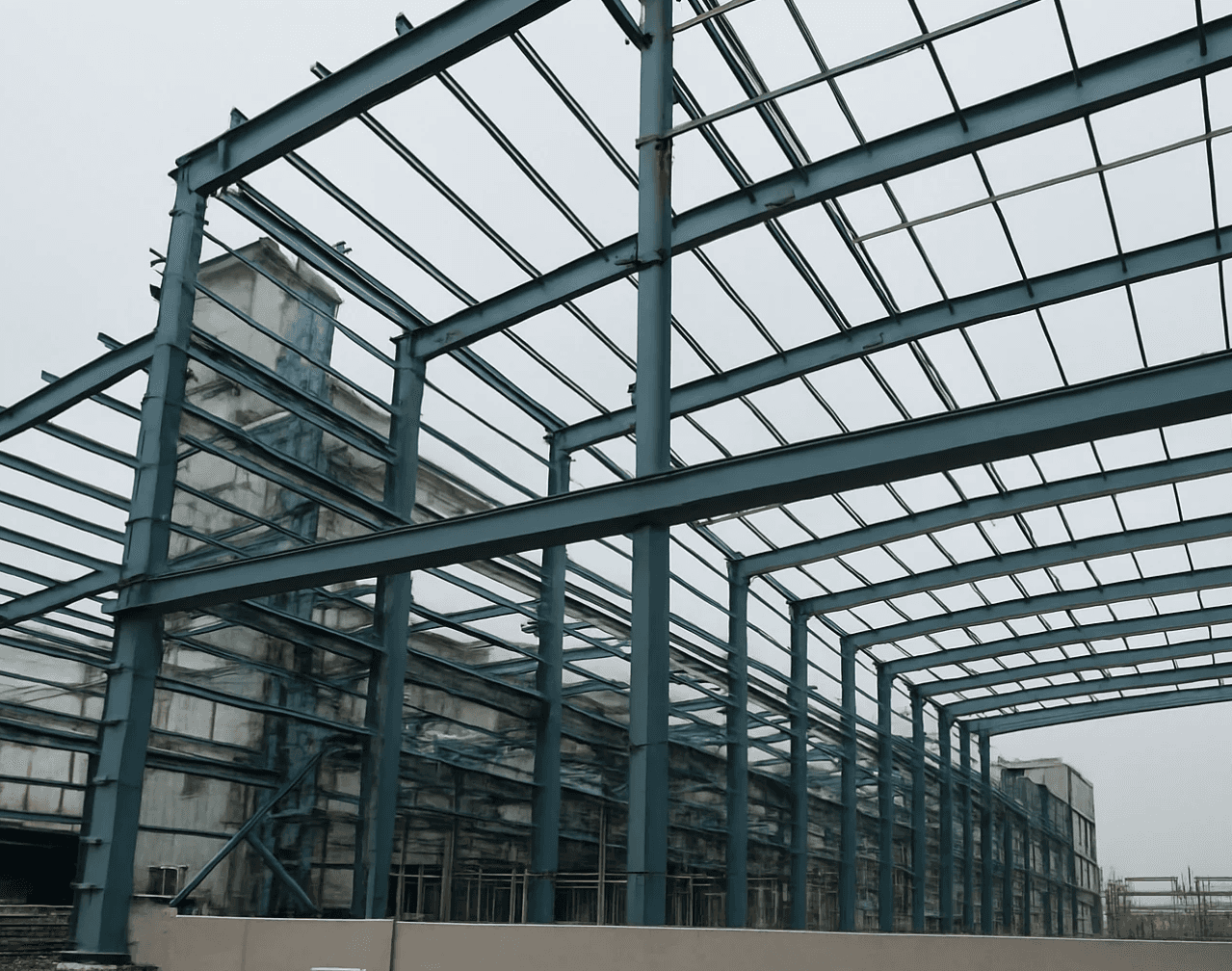

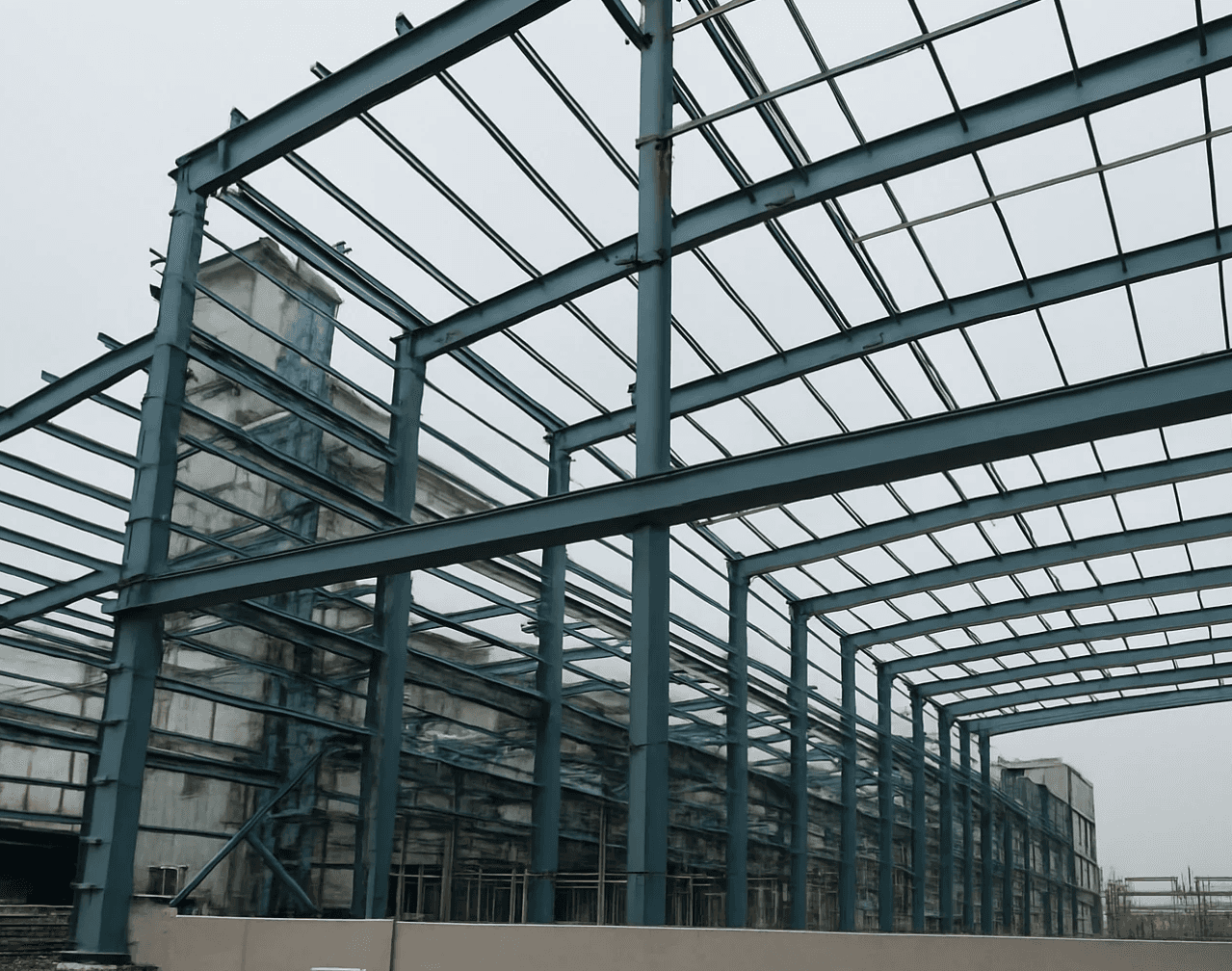

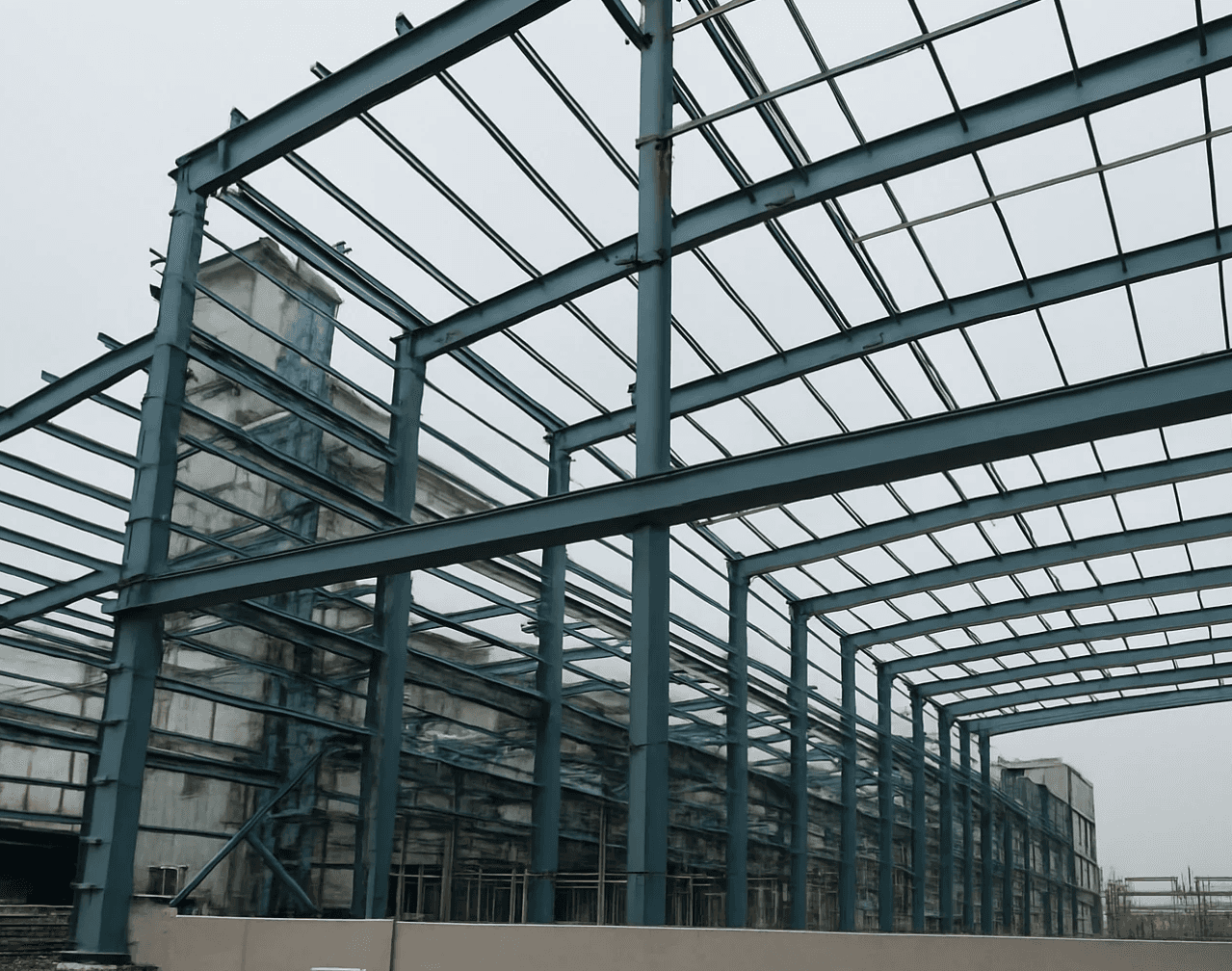

Lambda Engineering provided full structural and fabrication engineering for a large-span industrial steel structure designed to accommodate dual overhead cranes with rated capacities of 50 metric tons and 75 metric tons. The structure integrates heavy built-up steel members anchored over reinforced concrete pedestals and deep foundations to withstand both vertical and lateral crane loads.

Key Design Features

Structure Type: Steel portal frame with crane-supporting gantry girders.

Span Configuration: Approx. 25–30 m bay spacing, 18–20 m clear height.

Primary Members: Built-up I-sections for columns and rafters with end-plate bolted connections.

Gantry Girders: Custom lattice-type truss beams (painted red) designed for high load efficiency, supporting crane rails and wheel loads exceeding 350 kN per wheel.

Crane System: Two double-girder electric overhead traveling (EOT) cranes—50 MT and 75 MT—with integrated operator cabins and service platforms.

Foundation & Pedestals: Reinforced concrete grade beams and column pedestals engineered to absorb dynamic impact loads, surge forces, and lateral drift control.

Roof & Wall System: Cold-formed Z-purlins and C-girts supporting profiled sheeting; roof bracing to resist wind uplift and sway.

Lateral Stability: Full system of X-bracing and portal action with moment-resisting connections.

Engineering Highlights

Designed per AISC 360-16 and ACI 318-19 standards, with crane load verification per CMAA-70 Class D duty cycle.

Conducted 3D structural analysis (STAAD / SAP2000) for load combinations including impact, wind, and seismic actions.

Fabrication drawings and connection details were optimized for shop welding and on-site bolting for quick assembly.

Coordinated with MEP and crane installation teams to ensure alignment tolerances within ±3 mm along the runway.

Result

The resulting shed achieved exceptional structural stability and operational reliability under continuous crane duty cycles—an example of precision steel engineering and multidisciplinary coordination.