Pre-Eng. Buildings

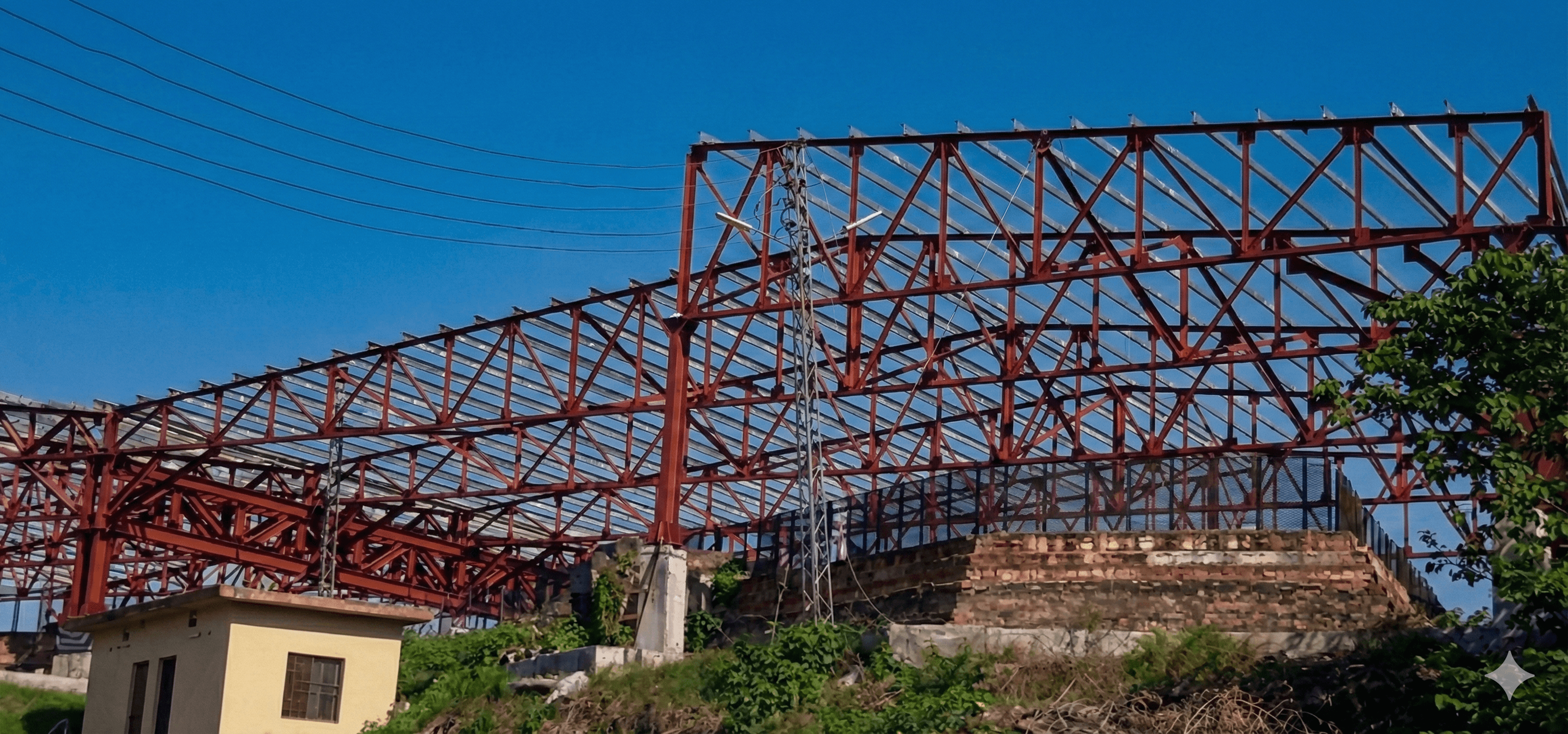

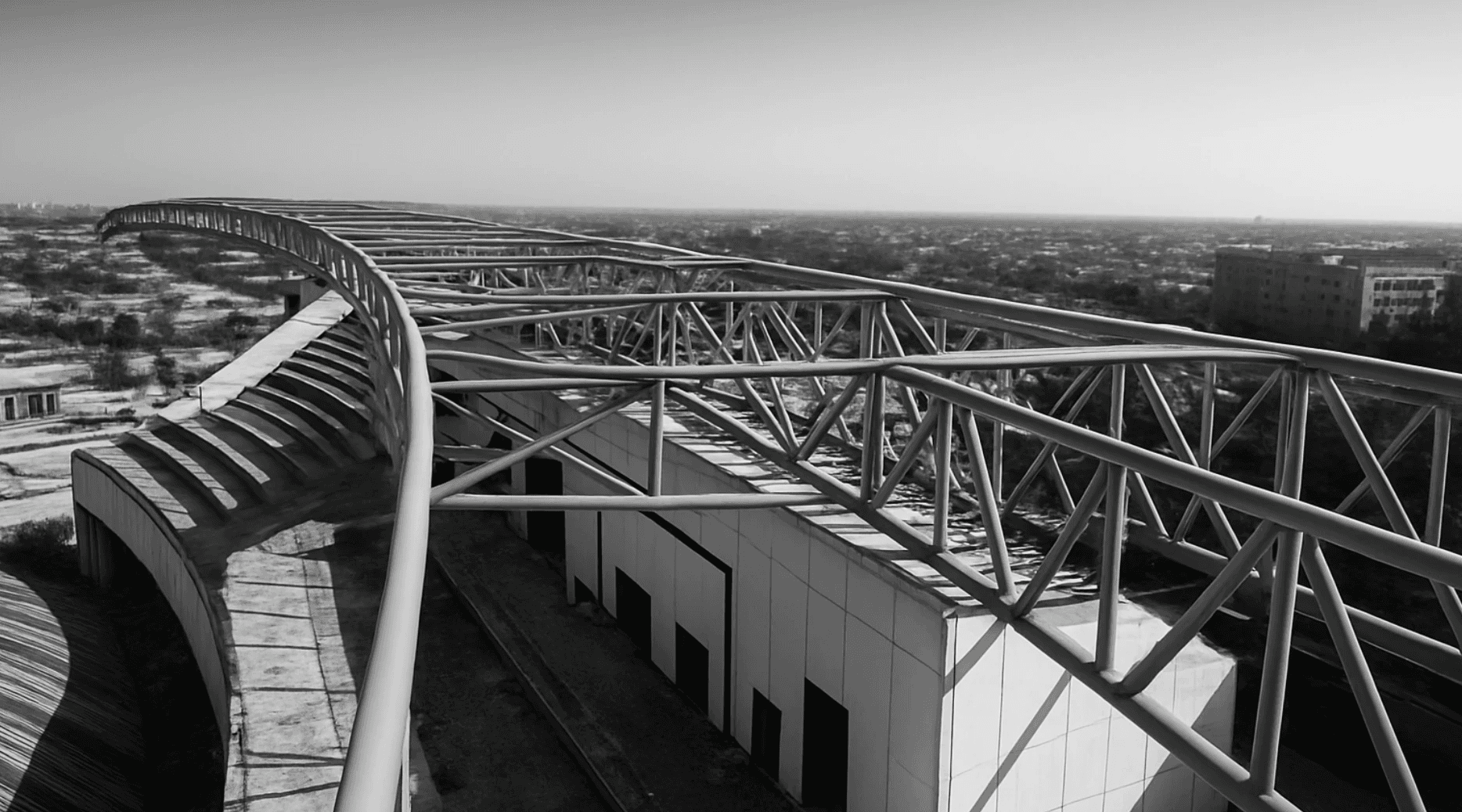

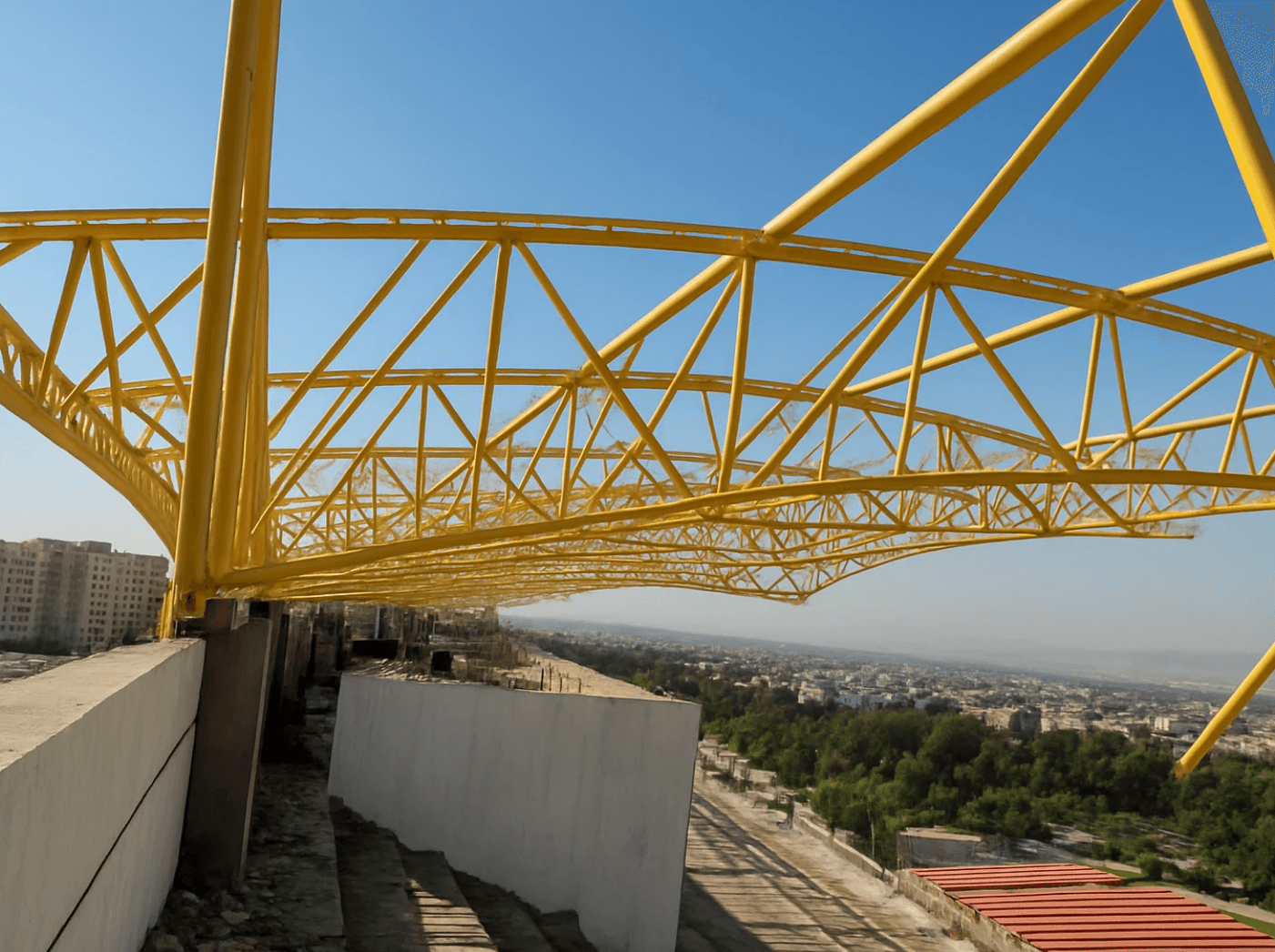

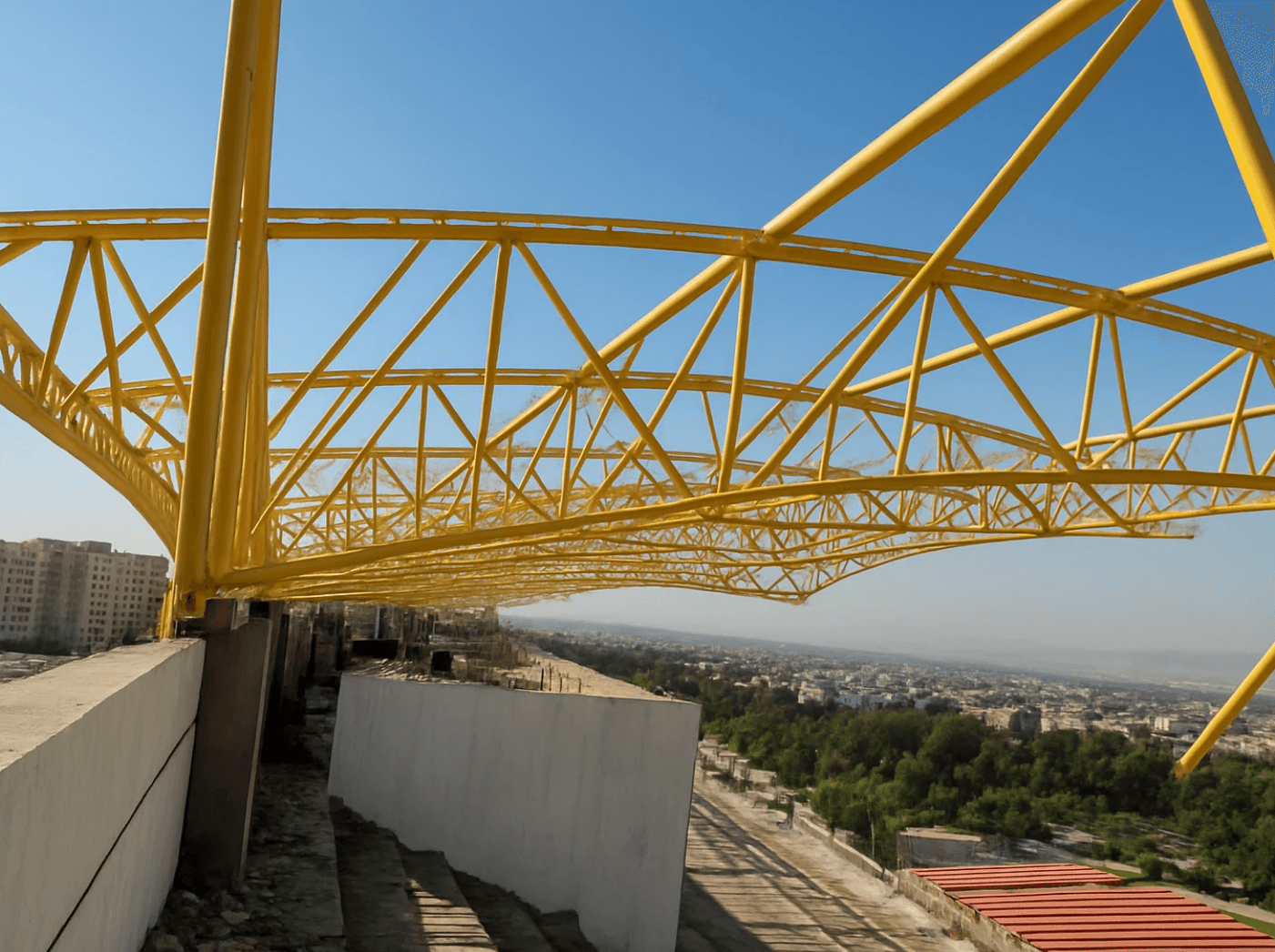

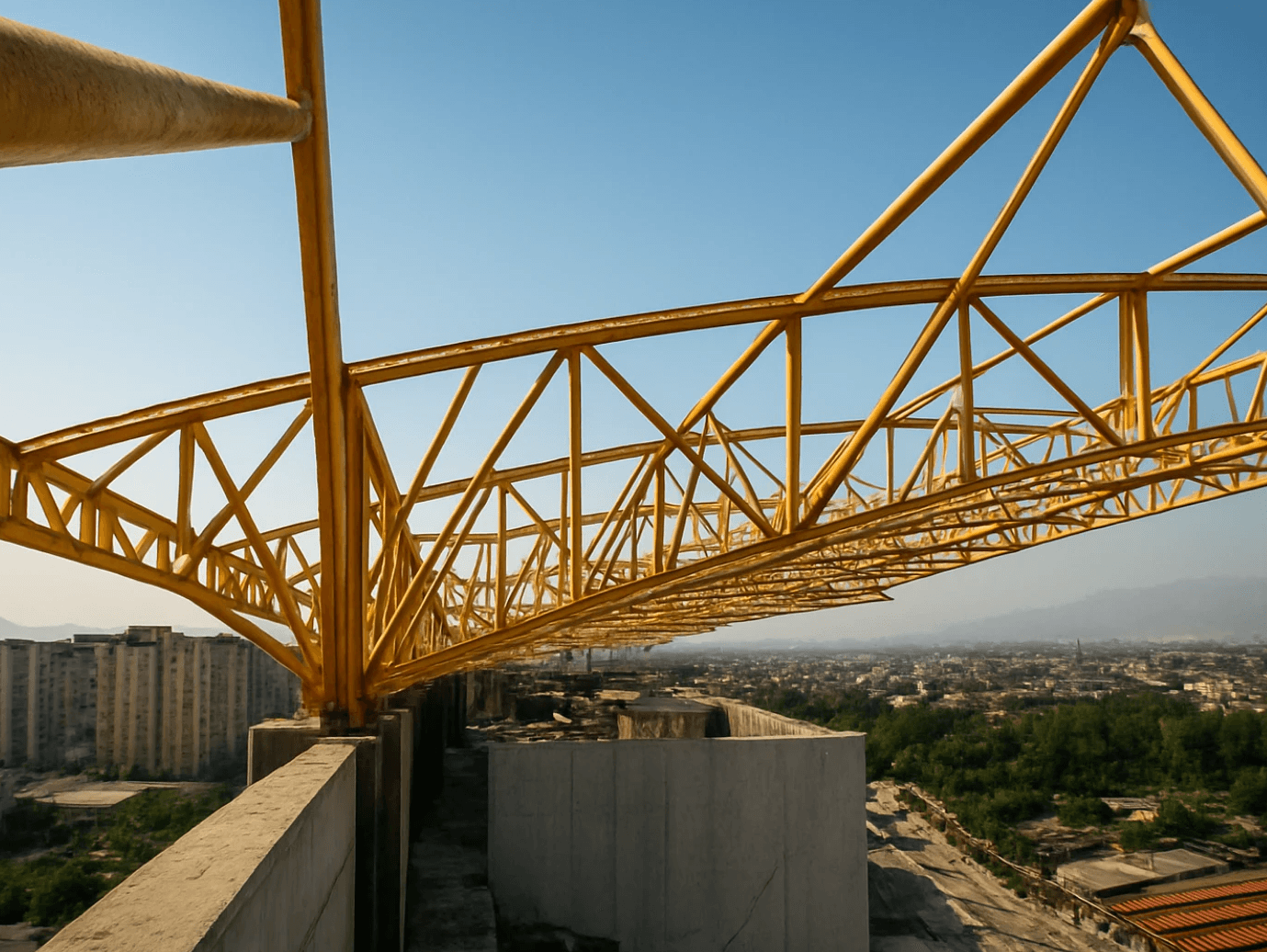

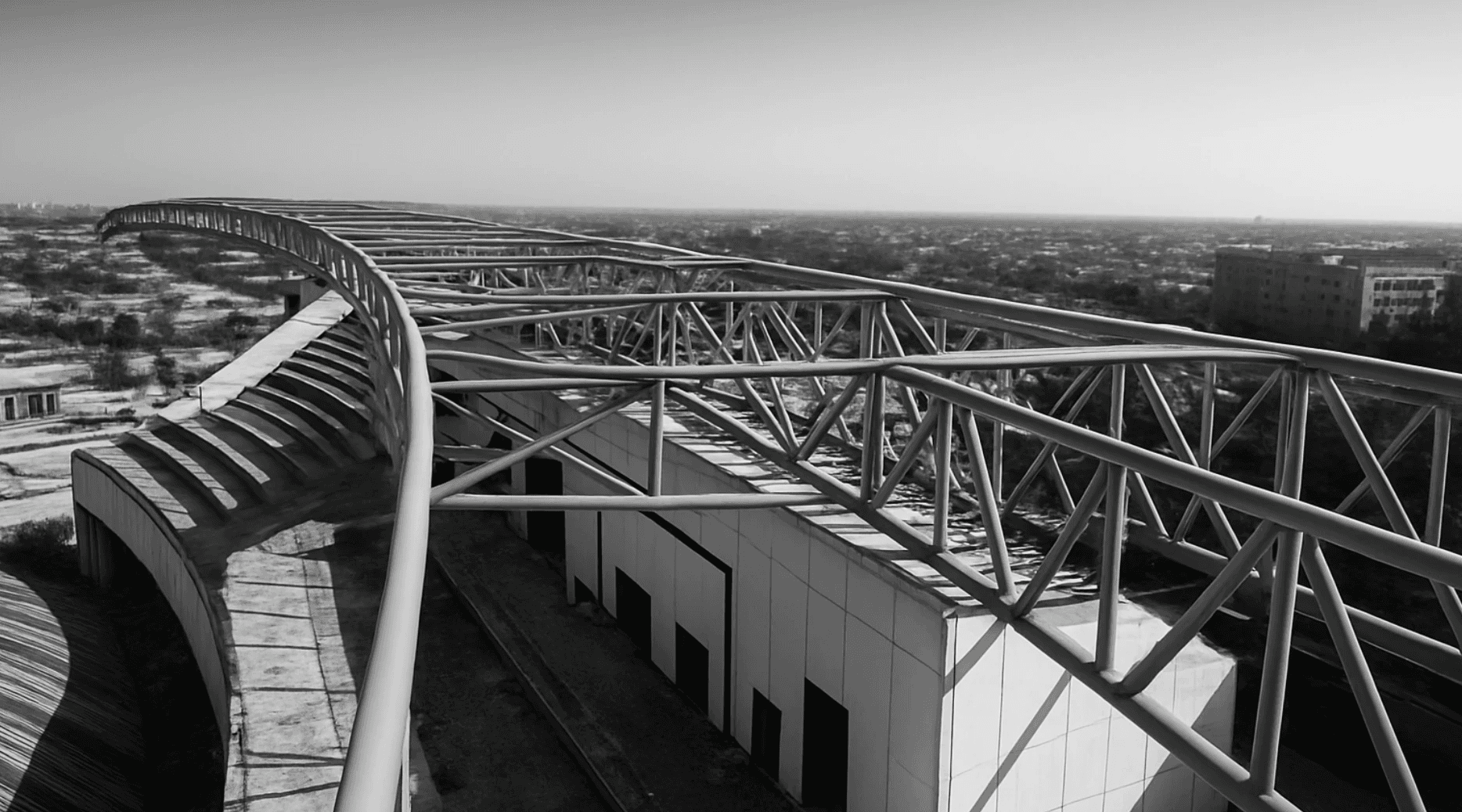

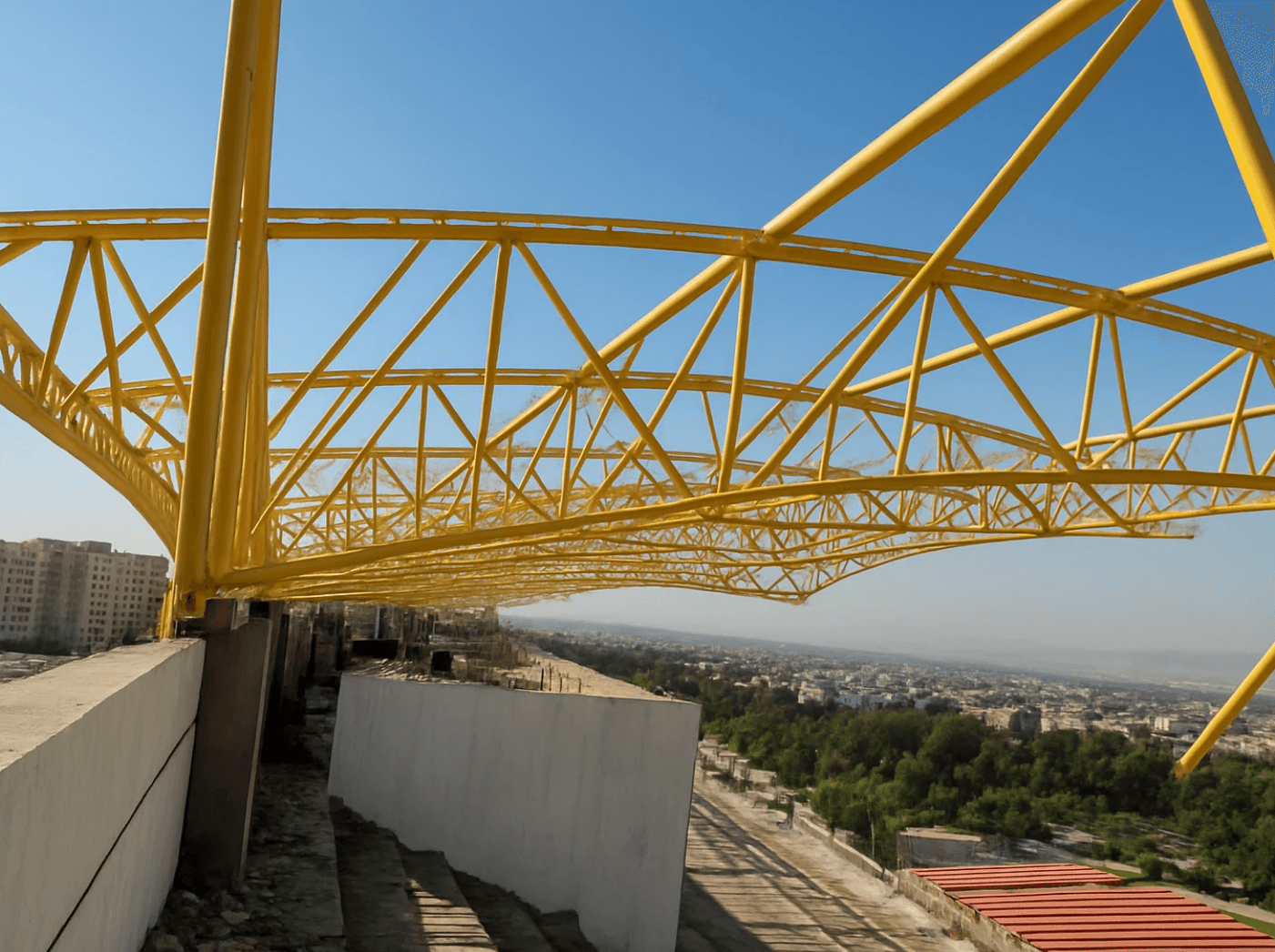

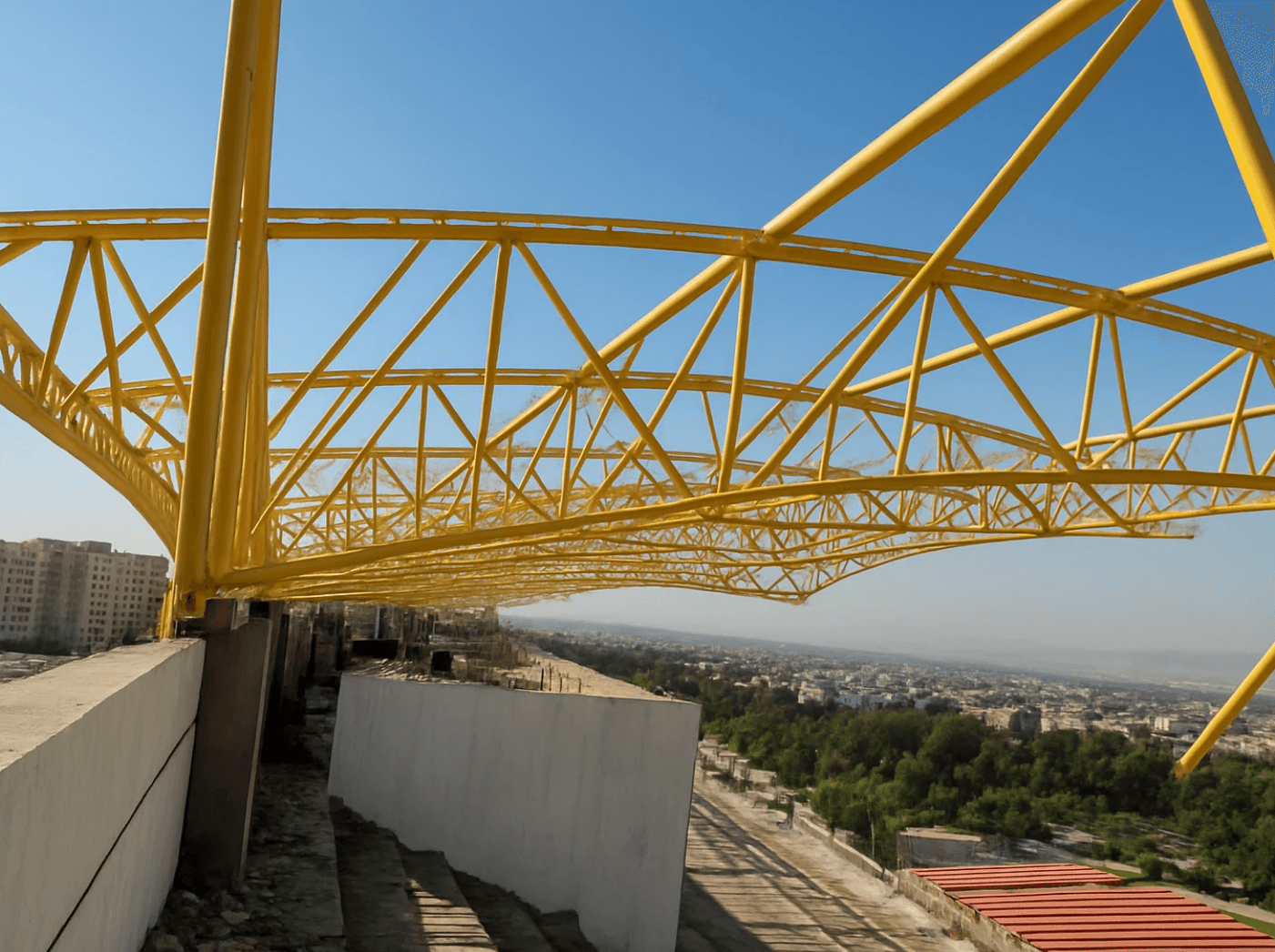

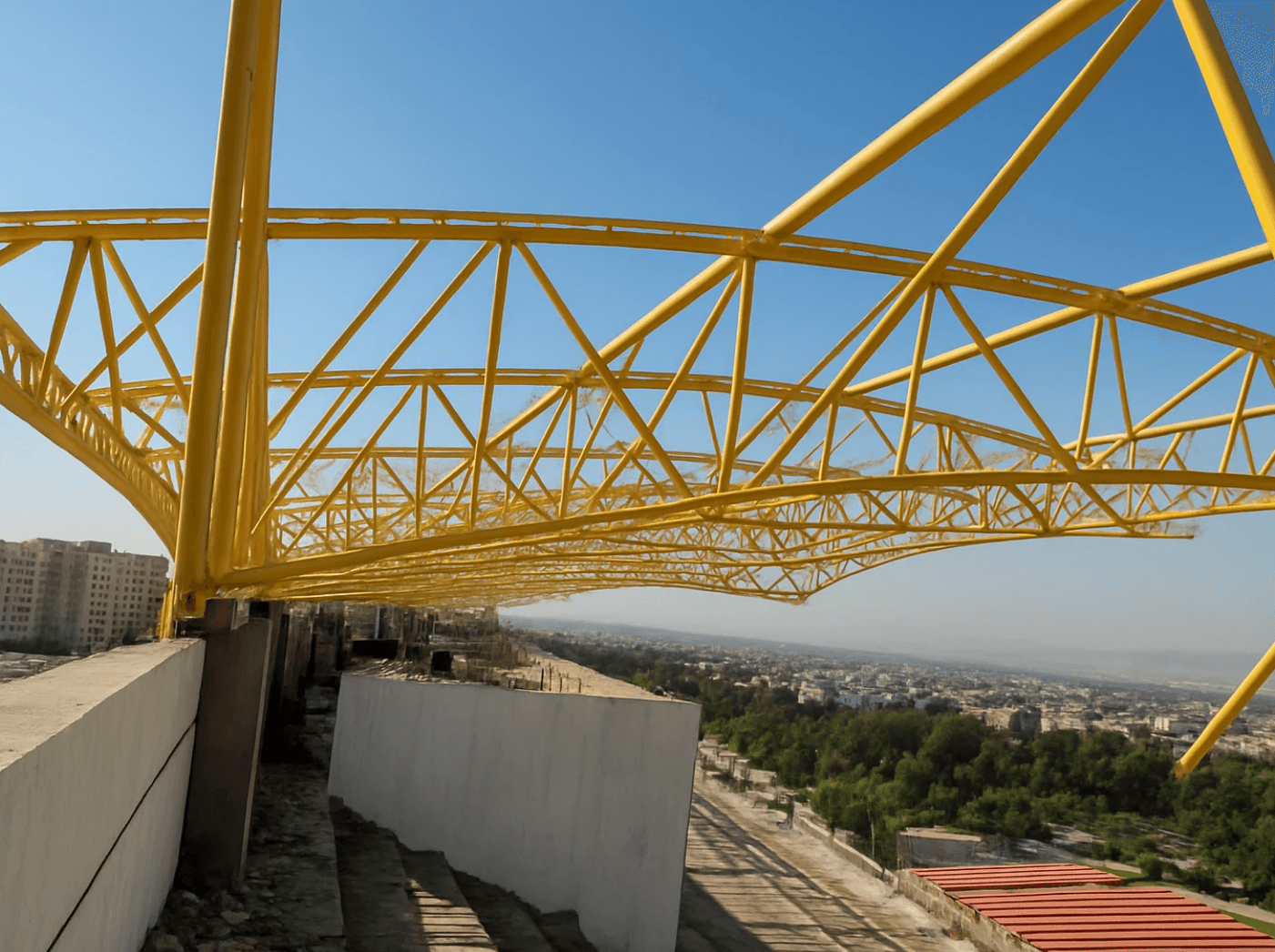

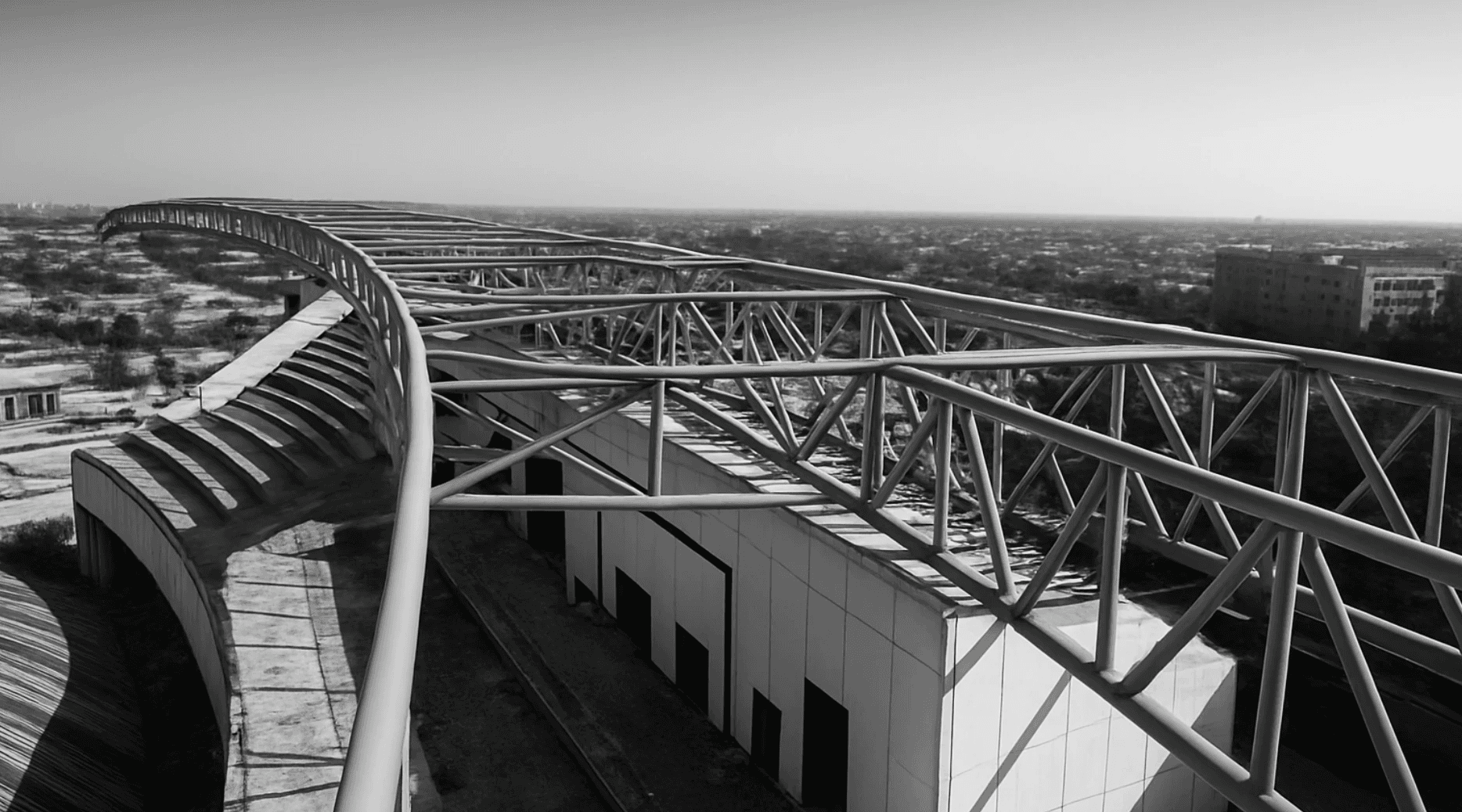

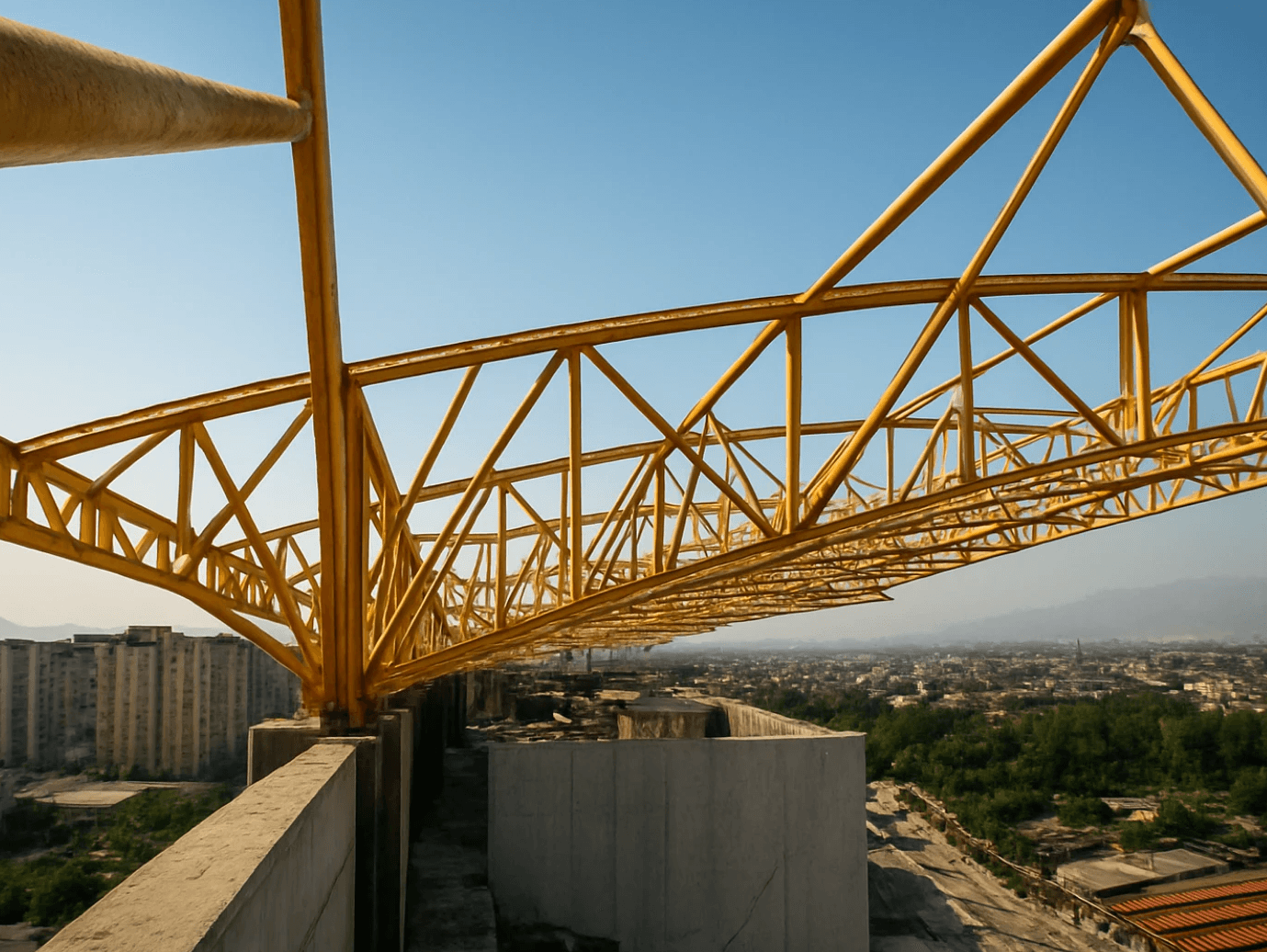

Stadium Roof Space Truss Structure

Stadium Roof Space Truss Structure

Stadium Roof Space Truss Structure

Truss roof structure with Tensile Fabric roof

Truss roof structure with Tensile Fabric roof

Truss roof structure with Tensile Fabric roof

Year

2024

Year

2024

Year

2024

Industry

Sports & Entertainment

Industry

Sports & Entertainment

Industry

Sports & Entertainment

Project Duration

4 weeks

Project Duration

4 weeks

Project Duration

4 weeks

Intro

Lambda Engineering designed and detailed a curved space truss roof system for a modern sports stadium, providing shelter to the spectator stands while maintaining a sleek, open architectural aesthetic. The roof structure spans large distances without intermediate supports, combining structural efficiency with visual elegance.

Key Design Features

Structural System: Curved steel space truss supported on reinforced concrete seating tiers.

Span & Geometry: Long-span (~40–50 meters) double-layer truss with parabolic curvature optimized for load distribution and architectural alignment.

Members: Circular hollow steel sections (CHS) and RHS profiles for primary and secondary members.

Connections: Full bolted node assemblies with prefabricated gusset joints for modular on-site assembly.

Roof Covering: Lightweight profiled sheets and translucent polycarbonate panels for natural lighting.

Support System: Anchored on RCC columns with base plates and shear keys designed for uplift resistance.

Wind & Load Design: Modeled per ASCE 7-16, with wind suction coefficients up to 1.5 due to roof curvature and open sides.

Fabrication Detailing: Node numbering, joint alignment, and pre-camber design executed through 3D modeling

Engineering Highlights

Structural design compliant with AISC 360-16 and BS EN 1993.

3D finite-element analysis performed for dead, live, and wind load combinations.

Deflection limits maintained at L/240 for live load to ensure roofing alignment.

Field assembly completed through modular pre-fabricated segments, reducing erection time and site welding.

Result

A high-performance, architecturally expressive roof system that blends engineering precision with visual fluidity, enhancing the stadium’s skyline while ensuring audience comfort and safety.

Latest Projects

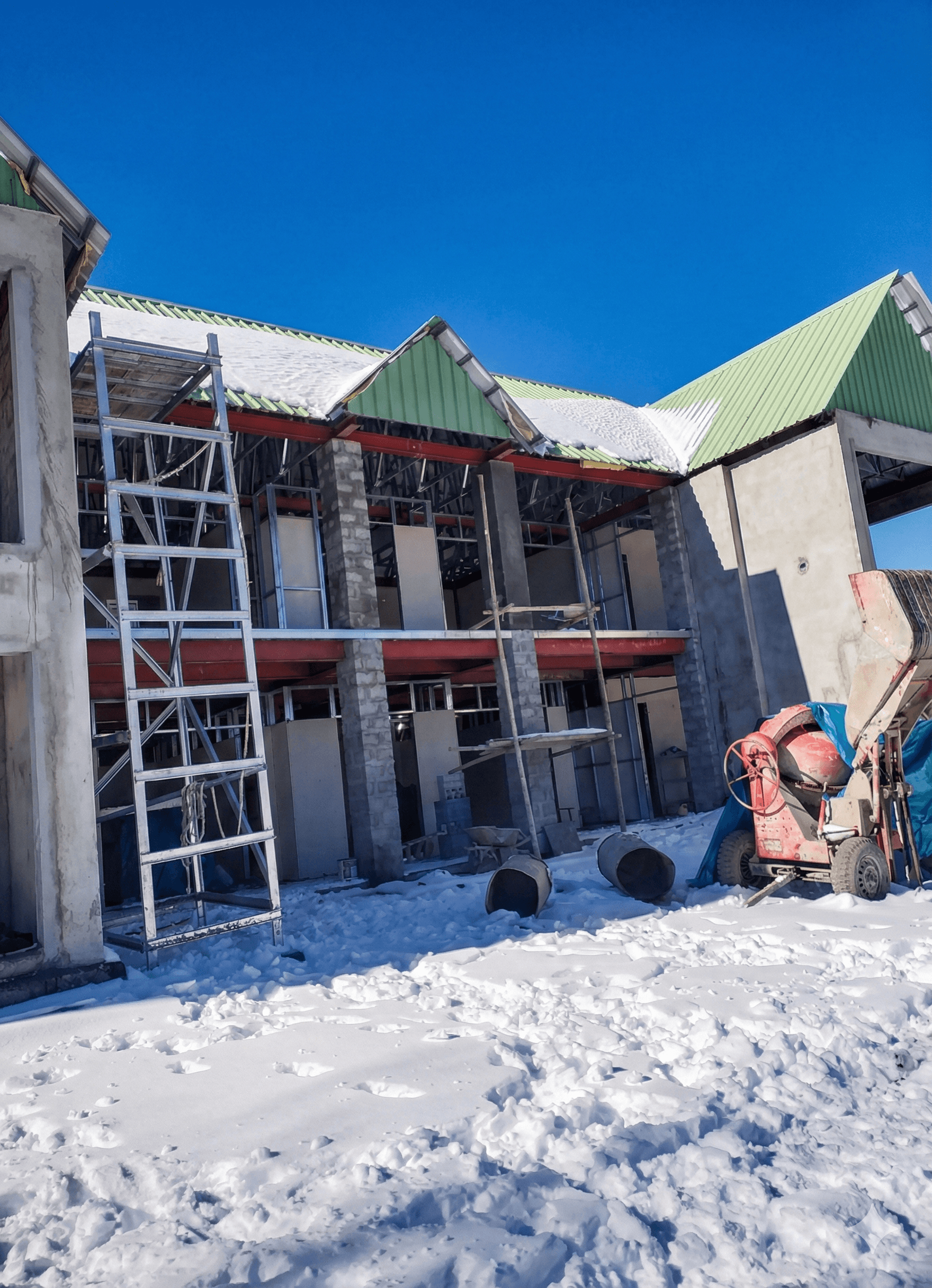

Pre-Eng. Buildings

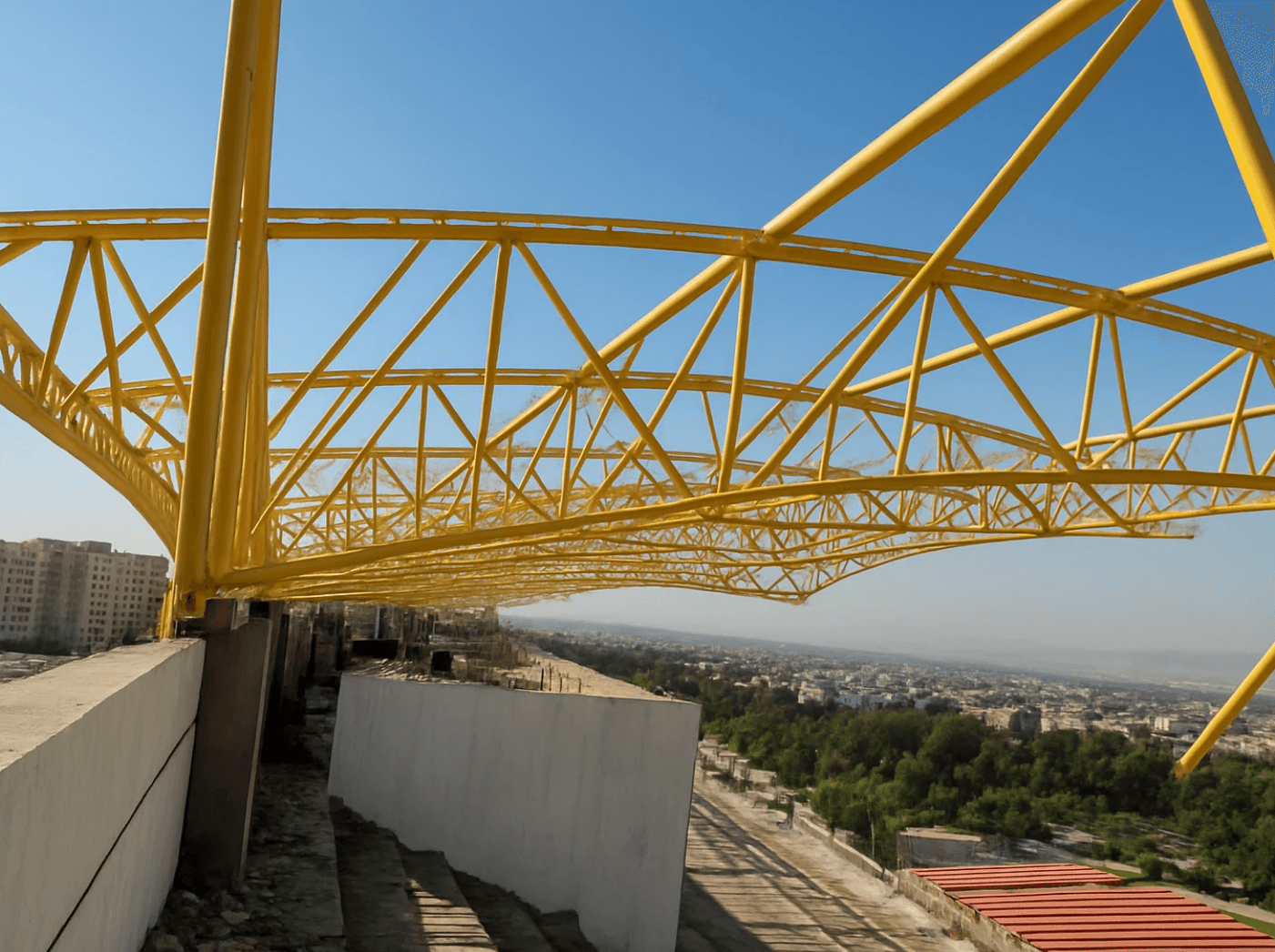

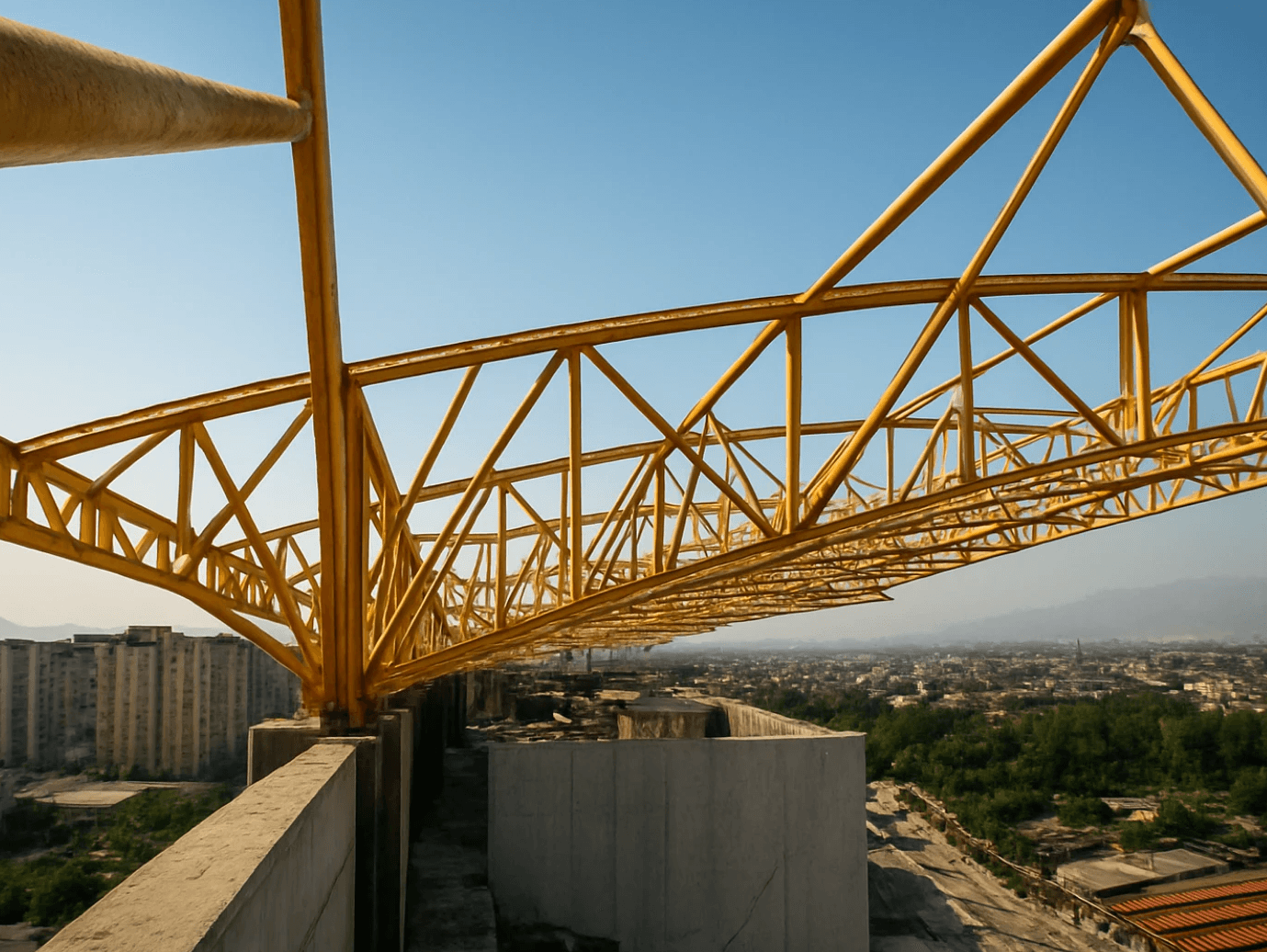

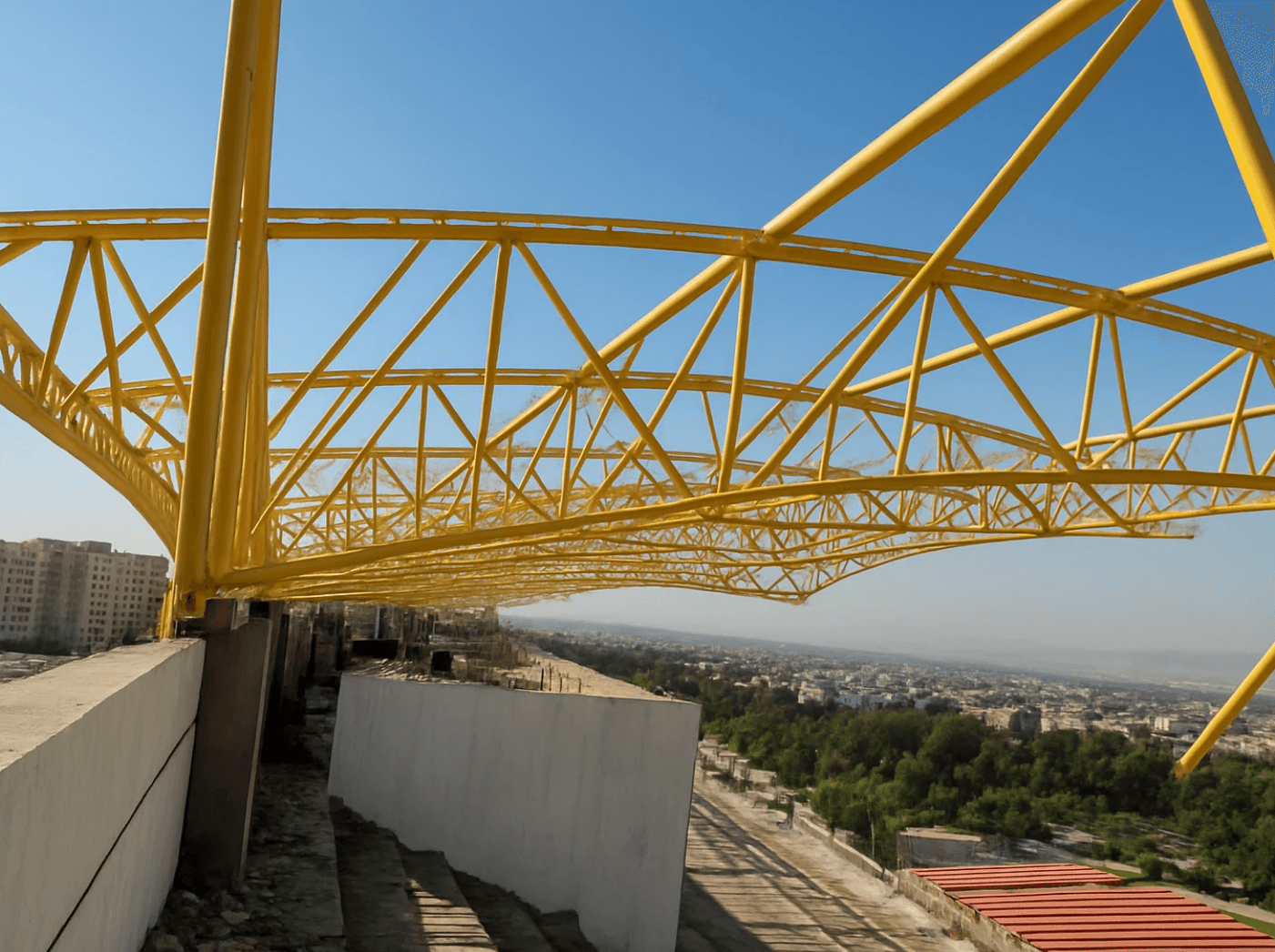

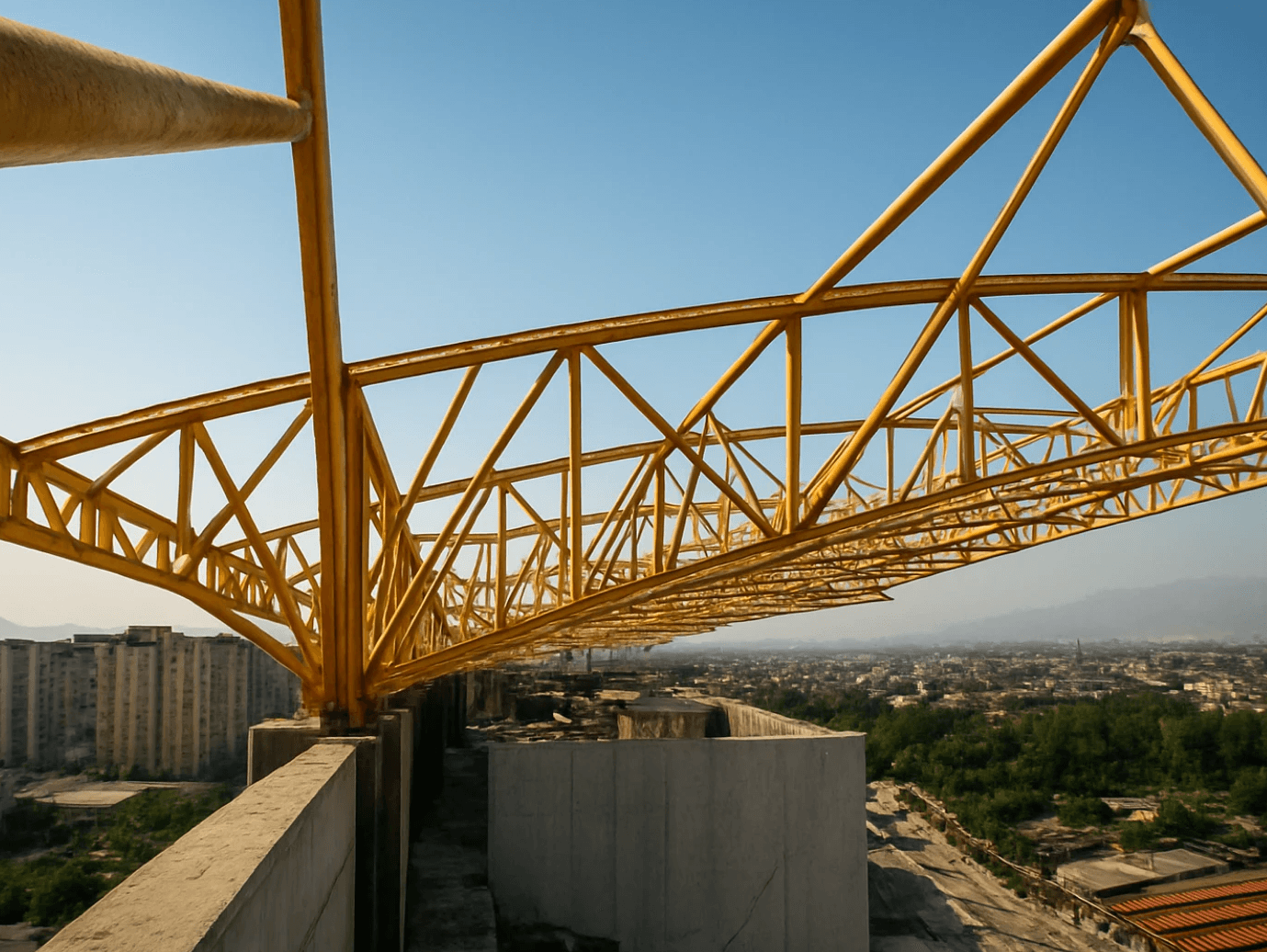

Stadium Roof Space Truss Structure

Stadium Roof Space Truss Structure

Stadium Roof Space Truss Structure

Truss roof structure with Tensile Fabric roof

Truss roof structure with Tensile Fabric roof

Truss roof structure with Tensile Fabric roof

Year

2024

Year

2024

Year

2024

Industry

Sports & Entertainment

Industry

Sports & Entertainment

Industry

Sports & Entertainment

Project Duration

4 weeks

Project Duration

4 weeks

Project Duration

4 weeks

Intro

Lambda Engineering designed and detailed a curved space truss roof system for a modern sports stadium, providing shelter to the spectator stands while maintaining a sleek, open architectural aesthetic. The roof structure spans large distances without intermediate supports, combining structural efficiency with visual elegance.

Key Design Features

Structural System: Curved steel space truss supported on reinforced concrete seating tiers.

Span & Geometry: Long-span (~40–50 meters) double-layer truss with parabolic curvature optimized for load distribution and architectural alignment.

Members: Circular hollow steel sections (CHS) and RHS profiles for primary and secondary members.

Connections: Full bolted node assemblies with prefabricated gusset joints for modular on-site assembly.

Roof Covering: Lightweight profiled sheets and translucent polycarbonate panels for natural lighting.

Support System: Anchored on RCC columns with base plates and shear keys designed for uplift resistance.

Wind & Load Design: Modeled per ASCE 7-16, with wind suction coefficients up to 1.5 due to roof curvature and open sides.

Fabrication Detailing: Node numbering, joint alignment, and pre-camber design executed through 3D modeling

Engineering Highlights

Structural design compliant with AISC 360-16 and BS EN 1993.

3D finite-element analysis performed for dead, live, and wind load combinations.

Deflection limits maintained at L/240 for live load to ensure roofing alignment.

Field assembly completed through modular pre-fabricated segments, reducing erection time and site welding.

Result

A high-performance, architecturally expressive roof system that blends engineering precision with visual fluidity, enhancing the stadium’s skyline while ensuring audience comfort and safety.

Latest Projects

Pre-Eng. Buildings

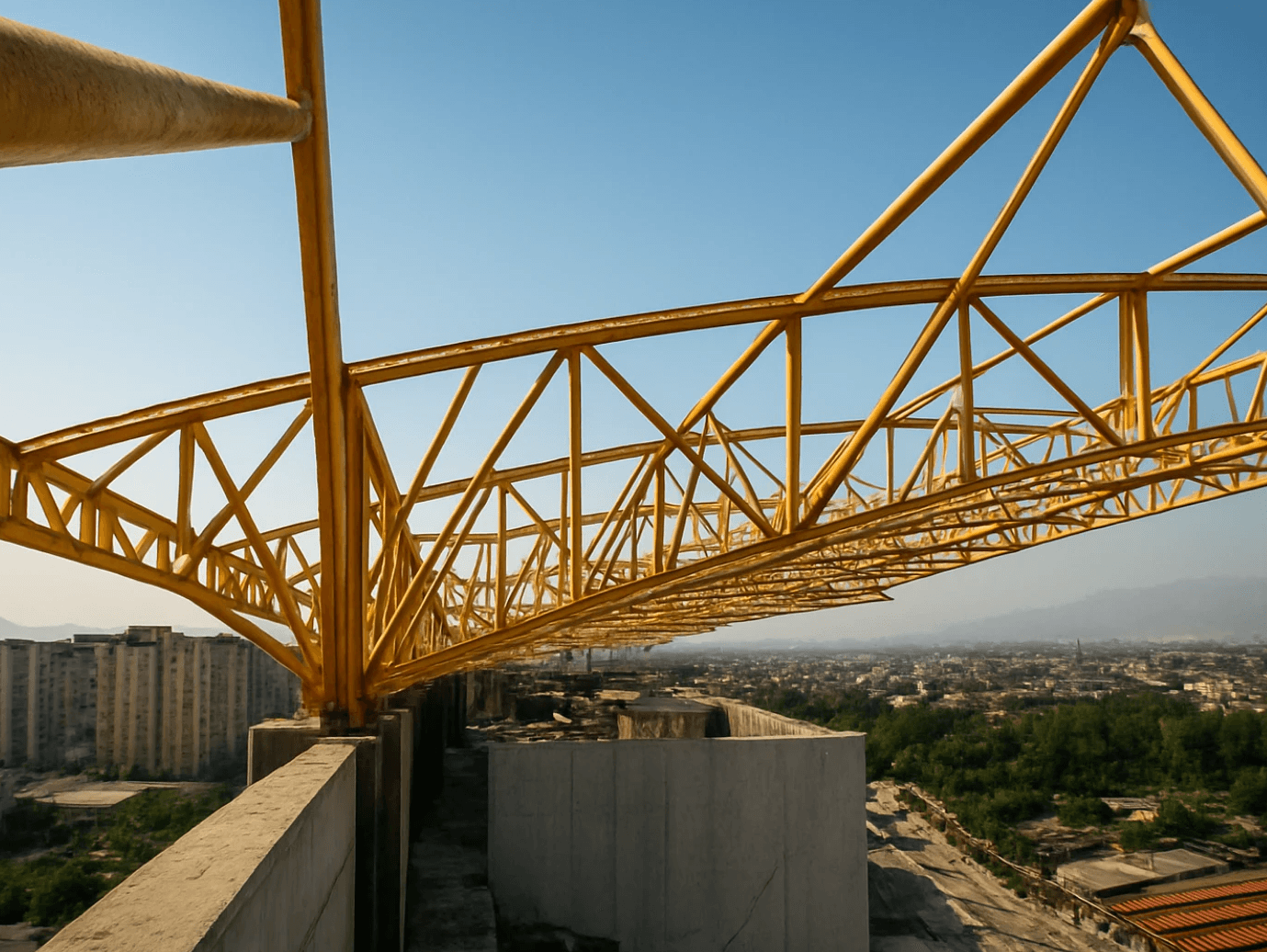

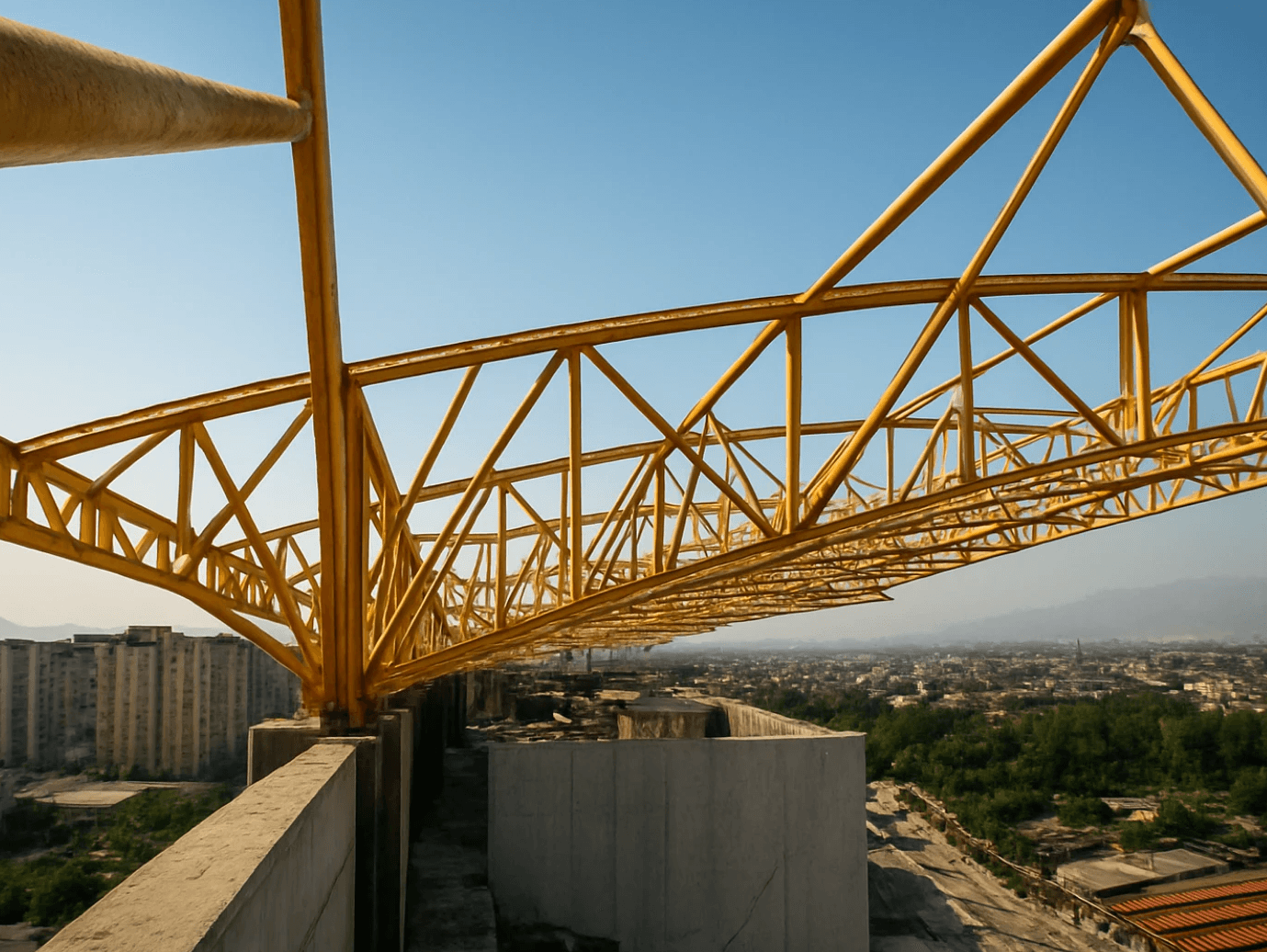

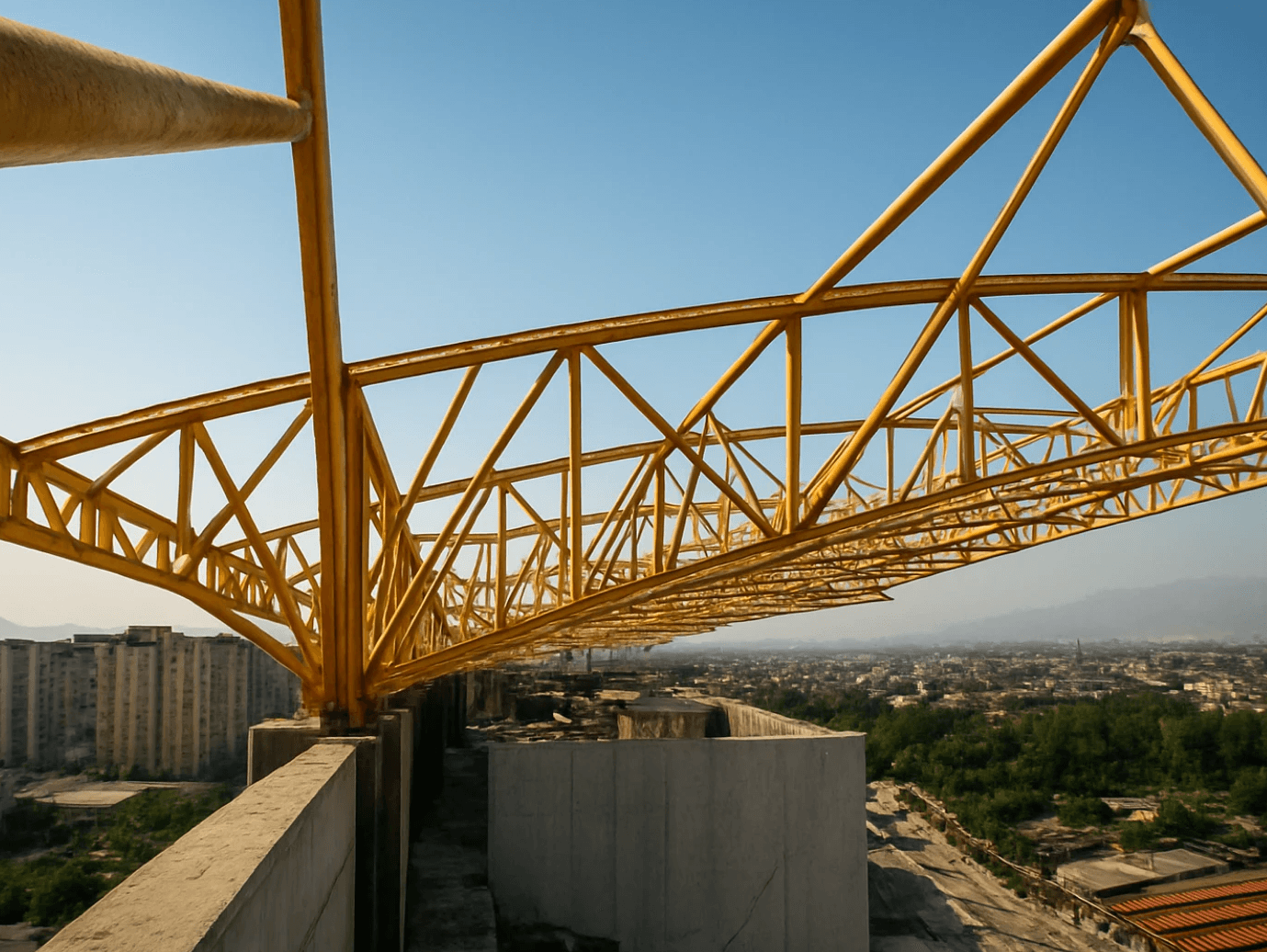

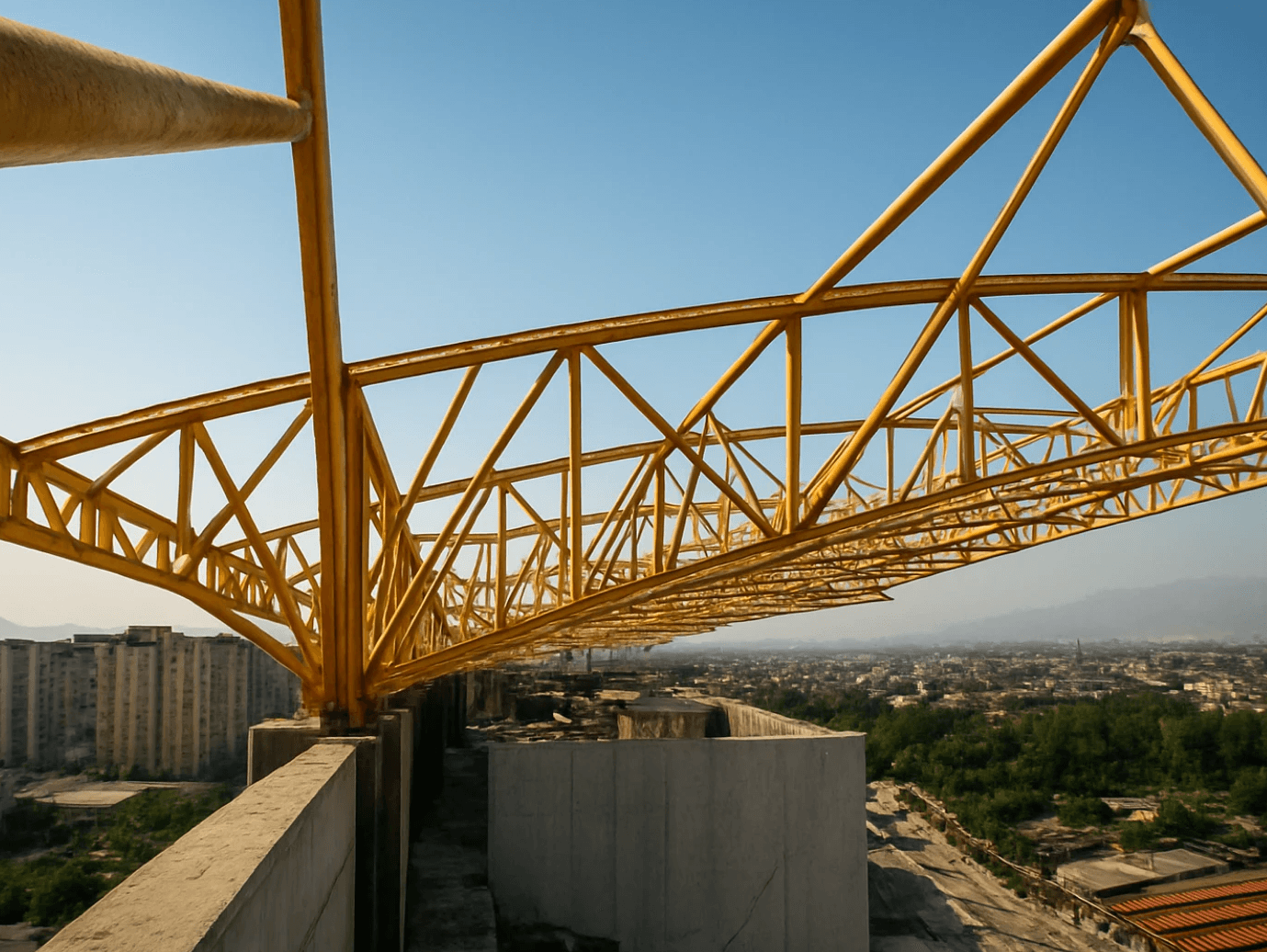

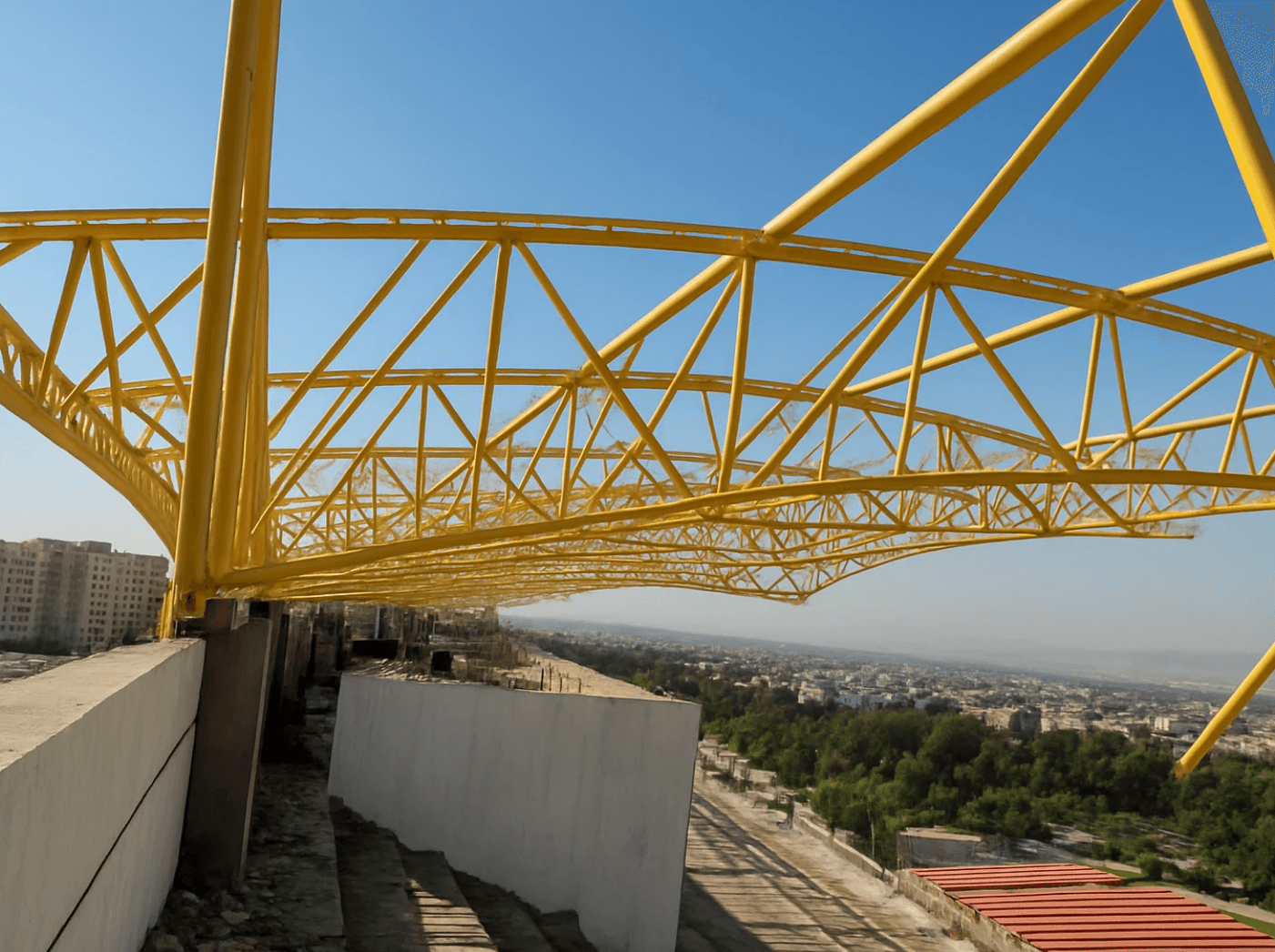

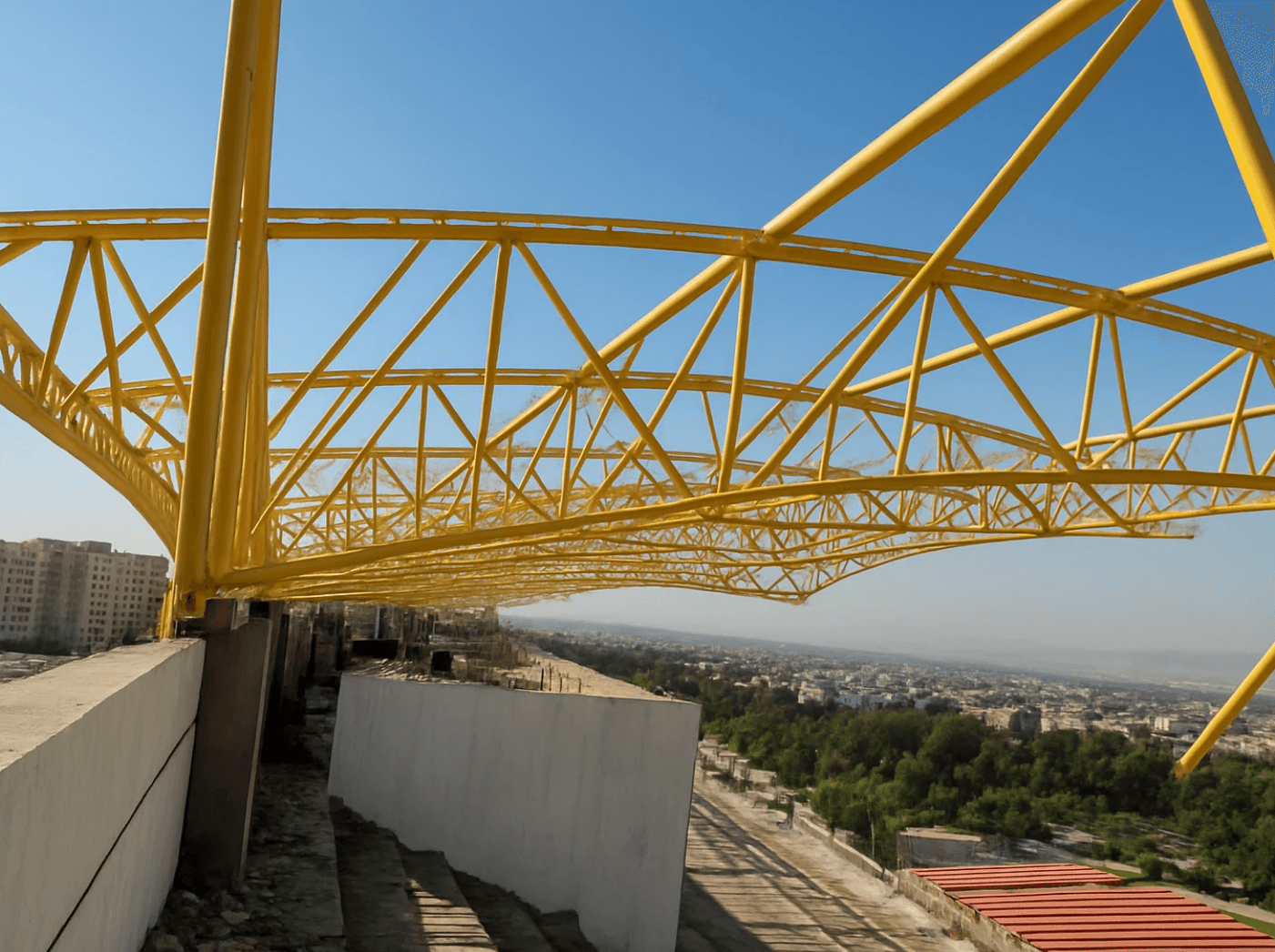

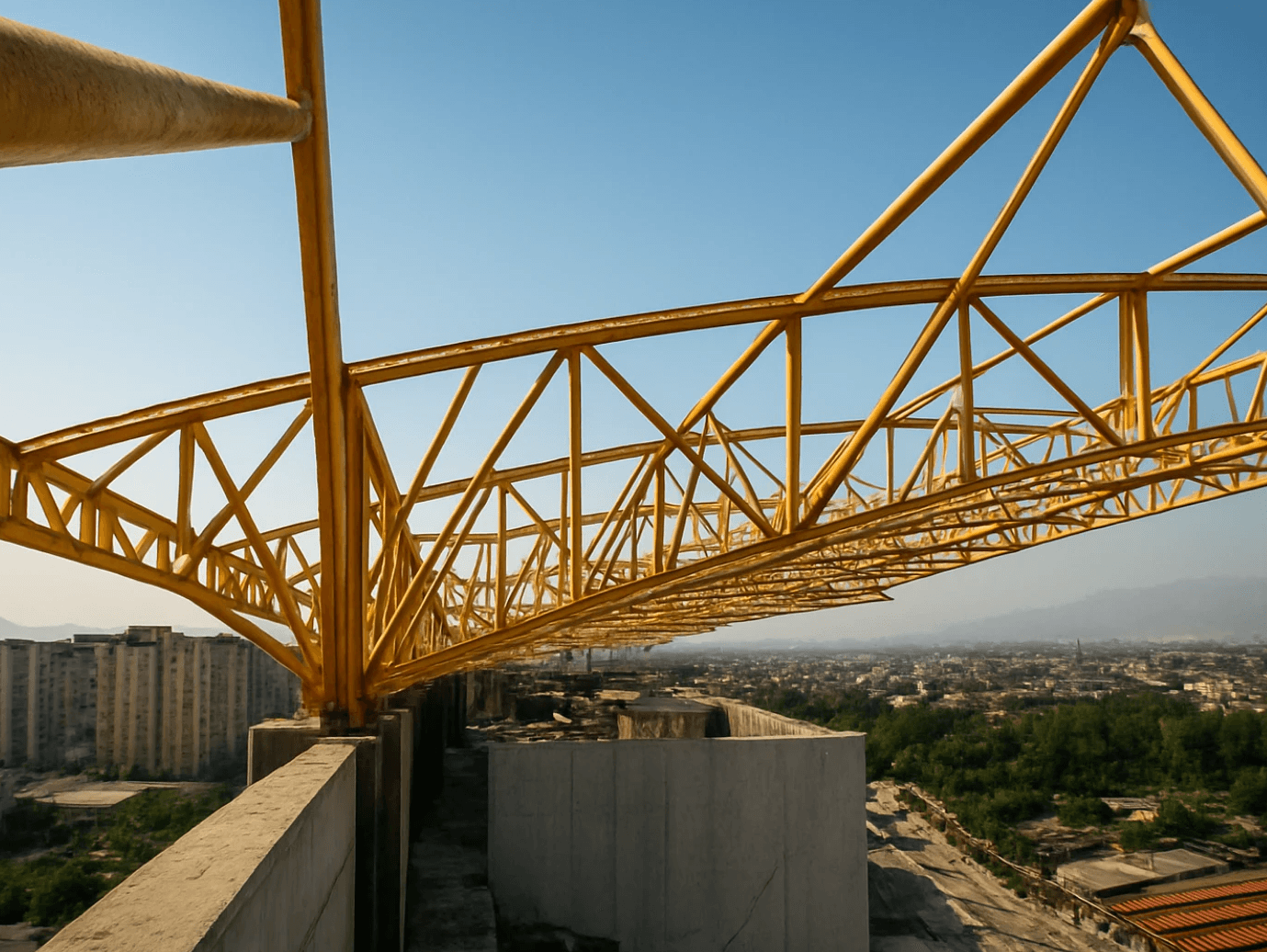

Stadium Roof Space Truss Structure

Stadium Roof Space Truss Structure

Stadium Roof Space Truss Structure

Truss roof structure with Tensile Fabric roof

Truss roof structure with Tensile Fabric roof

Truss roof structure with Tensile Fabric roof

Year

2024

Year

2024

Year

2024

Industry

Sports & Entertainment

Industry

Sports & Entertainment

Industry

Sports & Entertainment

Project Duration

4 weeks

Project Duration

4 weeks

Project Duration

4 weeks

Intro

Lambda Engineering designed and detailed a curved space truss roof system for a modern sports stadium, providing shelter to the spectator stands while maintaining a sleek, open architectural aesthetic. The roof structure spans large distances without intermediate supports, combining structural efficiency with visual elegance.

Key Design Features

Structural System: Curved steel space truss supported on reinforced concrete seating tiers.

Span & Geometry: Long-span (~40–50 meters) double-layer truss with parabolic curvature optimized for load distribution and architectural alignment.

Members: Circular hollow steel sections (CHS) and RHS profiles for primary and secondary members.

Connections: Full bolted node assemblies with prefabricated gusset joints for modular on-site assembly.

Roof Covering: Lightweight profiled sheets and translucent polycarbonate panels for natural lighting.

Support System: Anchored on RCC columns with base plates and shear keys designed for uplift resistance.

Wind & Load Design: Modeled per ASCE 7-16, with wind suction coefficients up to 1.5 due to roof curvature and open sides.

Fabrication Detailing: Node numbering, joint alignment, and pre-camber design executed through 3D modeling

Engineering Highlights

Structural design compliant with AISC 360-16 and BS EN 1993.

3D finite-element analysis performed for dead, live, and wind load combinations.

Deflection limits maintained at L/240 for live load to ensure roofing alignment.

Field assembly completed through modular pre-fabricated segments, reducing erection time and site welding.

Result

A high-performance, architecturally expressive roof system that blends engineering precision with visual fluidity, enhancing the stadium’s skyline while ensuring audience comfort and safety.